Buy Industrial Ventilation Fans Online

Buy Industrial Ventilation Fans Online

What Is a Heat Exchanger and How Does It Work?

Nov 14, 2025What Is a Heat Exchanger?

A heat exchanger is a piece of equipment used to transfer heat from one medium to another without direct contact between them. It is commonly found in boilers, ventilation systems, air dryers, and many industrial processes.

In factories and workshops, an industrial heat exchanger helps recover heat that would otherwise be lost, keeping systems efficient while lowering energy costs. Its function is simple—move heat from where it is not needed to where it can be reused.

How Does a Heat Exchanger Work?

The basic working principle of a heat exchanger involves heat transfer through a solid wall. One fluid releases heat as it cools down, while another absorbs that heat as it warms up. Depending on the application, heat exchangers can use air, water, oil, or steam as the medium.

For example

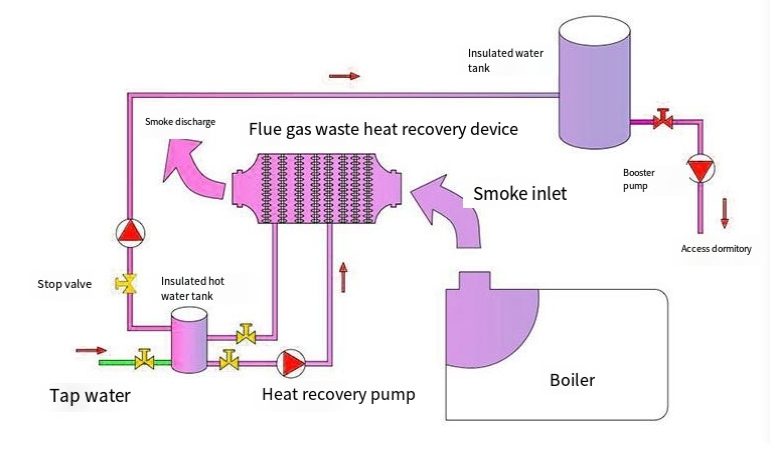

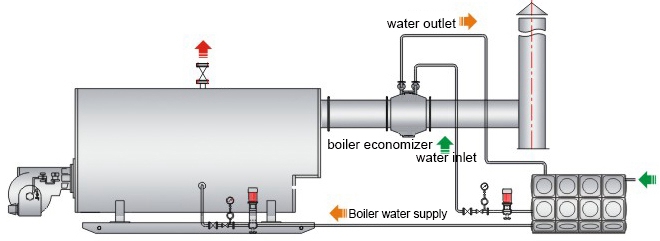

In boiler systems, an industrial heat exchanger recovers hot exhaust gases to preheat feedwater.

In air handling units, it warms or cools air before it enters the workspace.

In drying or food processing, it ensures uniform temperature distribution for product quality and energy savings.

Because the fluids do not mix, the process stays clean, safe, and reliable—especially important for chemical and food applications. In factory boiler systems, flus gas heat exchanger help recover exhaust heat to improve energy efficiency.

Main Types of Heat Exchangers

Different structures are designed for different uses:

Shell and Tube Heat Exchanger – Common in power plants and heavy industries, using tubes for efficient heat flow.

Plate Heat Exchanger – Compact and ideal for HVAC and light industrial applications.

Fin Tube Heat Exchanger – Used where air and gas heat exchange is required, such as in air heaters or condensers.

Air-Cooled Heat Exchanger – Uses ambient air instead of water, suitable for dry environments.

Choosing the right industrial heat exchanger depends on factors such as medium type, temperature, pressure, and installation space.

Why Are Industrial Heat Exchangers Important?

An efficient heat exchanger can cut energy consumption by up to 20–30%, reduce equipment wear, and improve production stability. It also supports global sustainability goals by minimizing carbon emissions from heating and cooling processes.

Modern heat exchangers use high-conductivity materials, anti-corrosion coatings, and modular designs that make cleaning and maintenance easier—ensuring long-term reliability in demanding environments.

Heat exchangers are the backbone of many heating and cooling systems. Understanding how they work helps engineers and plant managers find smarter ways to save energy and improve system performance. Whether used for boilers, ventilation, or air-drying equipment, an industrial heat exchanger remains one of the most practical tools for achieving efficient and sustainable operation.

Learn more about our custom heat exchanger solutions for industrial energy-saving projects.

Hi! Click one of our members below to chat on