Buy Industrial Ventilation Fans Online

Buy Industrial Ventilation Fans Online

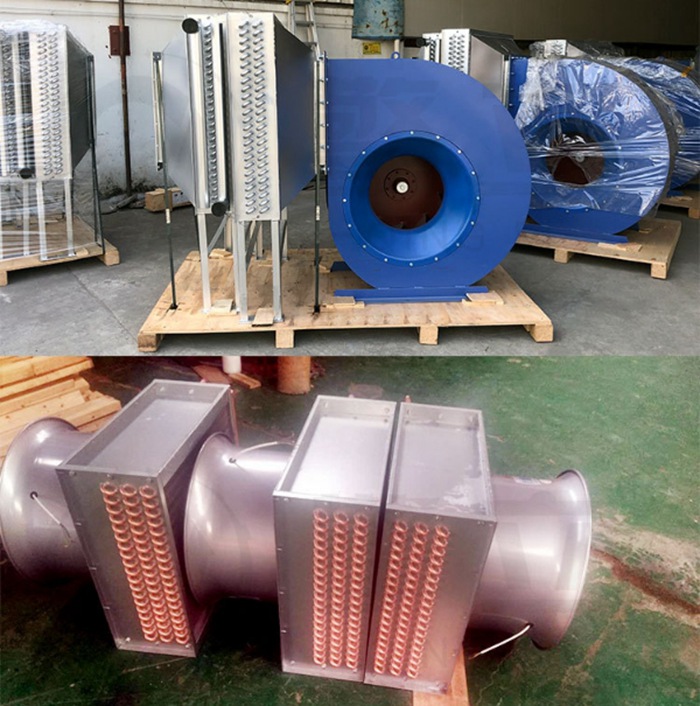

The finned tube heat exchanger is a high-efficiency heat exchanger for air heating and drying in oven and air hood systems. As a reliable heat exchanger, it boasts large heat exchange surfaces and excellent thermal conductivity.It operates with steam, hot water,or thermal oil as heating media, ensuring fast heat transfer, low energy loss, and stable performance.

Type :

Heat ExchangerPayment :

T/TOrder(MOQ) :

1 PCShipping Port :

GuangZhou, FoShanLead Time :

7-15 daysProduct Origin :

ChinaSteam Finned Tube Heat Exchanger for Oven Air Heating System

The finned tube heat exchanger is a high-efficiency heat exchanger for air heating and drying in oven and air hood systems. As a reliable heat exchanger, it boasts large heat exchange surfaces and excellent thermal conductivity.It operates with steam, hot water,or thermal oil as heating media, ensuring fast heat transfer, low energy loss, and stable performance.

Available in carbon steel, stainless steel 304, copper, and aluminum, our finned tube heat exchanger products support OEM customization with flexible size and design options. Factory direct supply ensures reliable performance and long service life for diverse industrial applications.

Specification:

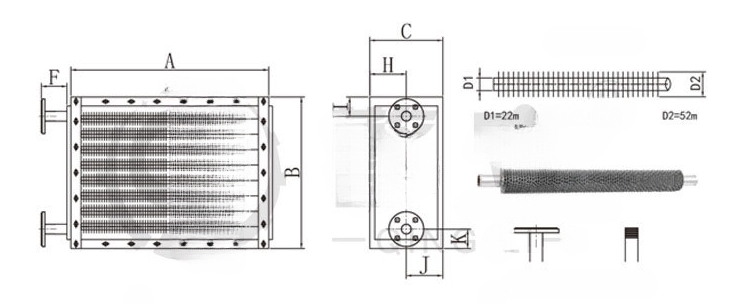

| Model SRZ | New Model QLZ QLL | Area (m²) | Size(mm) | Weight (Kg) |

Row | PCs each Row | ||

| A | B | C | ||||||

| 5x5D | 5x5x3 | 10.13 | 573 | 562 | 180 | 54 | 3 | 8 |

| 10x5D | 10x5x3 | 19.92 | 1067 | 93 | ||||

| 12x5D | 12x5x3 | 24.86 | 1316 | 113 | ||||

| 6X6D | 6X6X3 | 15.33 | 1067 | 688 | 180 | 77 | 3 | 10 |

| 10x6D | 10x6x3 | 25.13 | 675 | 115 | ||||

| 12X6D | 12X6x3 | 31:35 | 1316 | 139 | ||||

| 15x6D | 15x6x3 | 37.73 | 1571 | 164 | ||||

| 7x7D | 7x7x3 | 20.31 | 776 | 772 | 180 | 97 | 3 | 11 |

| 10x7D | 10x7x3 | 28.59 | 1067 | 129 | ||||

| 12x7D | 12x7x3 | 35.67 | 1316 | 156 | ||||

| 15x7D | 15x7x3 | 42.93 | 1571 | 183 | ||||

| 17x7D | 17x7x3 | 49.90 | 1816 | 210 | ||||

| 22x7D | 22x7x3 | 62.75 | 2268 | 260 | 3 | 11 | ||

Performance Parameters

Steam pressure ≤ 0.8 MPa

Hot air outlet temperature ≤ 150°C

Customizable air volume, flow direction, and tube arrangement

Optimized for drying lines, air supply systems, and heat recovery units

Benefit:

1.High heat transfer efficiency and fast thermal response

2.Compact structure with extended fin surface for larger exchange area

3.Long service life and stable operation under high temperature and pressure

4.Suitable for steam, hot water, or thermal oil as heat medium

5.several material available:carbon steel, stainless steel 304, copper, aluminum

6.Easy installation and low maintenance cost

7.OEM customization available for non-standard sizes

Used mainly for air heating in drying and oven systems, this radiator is the core component of industrial hot air equipment.It transfers heat from steam or thermal oil to the airflow, ensuring uniform temperature distribution in drying chambers and ventilation ducts.

Structure

The radiator adopts spiral finned tubes wound mechanically on seamless steel pipes (18 mm).Each fin strip (0.5×10 mm steel or stainless steel) is hot-dip galvanized to improve corrosion resistance.Optional SRZ type (steel fin) or SRL type (steel-aluminum composite fin) designs are available.The SRL type offers a larger heat exchange area per unit length than the SRZ type, improving efficiency in compact installations.

Customization & Support

1. There are design drawings and equipment drawings, only need to send your drawings to our customer service or technical staff, we will be in accordance with your requirements for the program quotation!

2. Air volume, air inlet condition, shape size, chilled water inlet temperature, cooling supply (or air outlet condition requirements) and other parameters provided by the design drawings, or provide the corresponding parameters according to our measurement drawing.

3. As long as the process requirements of your process parameters to inform our customer service or technical personnel, our company can provide technical advice at any time!

| Material | Pipe | Fin | Fin-Pipe | ||

| Carbon steel | ø18*2.0mm | 10*0.3mm 12*0.3mm 15*0.3mm |

ø18*2.0-0.38mm | ||

| ø22*2.0mm | ø22*2.0-0.42mm | ø22*2.0-0.46mm | ø22*2.0-0.52mm | ||

| ø25*2.0mm | ø25*2.0-0.45mm | ø25*2.0-0.49mm | ø25*2.0-0.55mm | ||

| ø32*3.0mm | ø32*3.0-0.52mm | ø32*3.0-0.56mm | ø32*3.0-0.62mm | ||

| ø42*3.0mm | ø42*3.0-0.62mm | ø42*3.0-0.66mm | ø42*3.0-0.72mm | ||

| ø48*3.0mm | ø48*3.0-0.68mm | ø48*3.0-0.72mm | ø48*3.0-0.78mm | ||

| ø60*4.0mm | ø60*4.0-0.80mm | ø60*4.0-0.84mm | ø60*4.0-0.90mm | ||

| Stainless steel 304 | ø18*2.0mm | 10*0.3mm 12*0.3mm 15*0.4mm |

ø18*2.0-0.38mm | ||

| ø22*2.0mm | ø22*2.0-0.42mm | ø22*2.0-0.52mm | |||

| ø25*2.0mm | ø25*2.0-0.45mm | ø25*2.0-0.55mm | |||

| ø42*4.0mm | ø42*4.0-0.62mm | ø42*4.0-0.72mm | |||

| ø48*4.0mm | ø48*4.0-0.68mm | ø48*4.0-0.78mm | |||

| ø60*4.0mm | ø60*4.0-0.80mm | ø60*4.0-0.90mm | |||

| Carbon steel with aluminum | ø18*2.0mm | ø18*2.0-0.38mm | |||

| ø22*2.0mm | height:12mm thickness:0.3-0.4mm |

ø22*2.0-0.46mm | |||

| ø25*2.0mm | height:12.5mm thickness:0.3-0.4mm |

ø25*2.0-0.50mm | |||

| ø25*2.0mm | height:15mm thickness:0.3-0.4mm |

ø25*2.0-0.55mm | |||

| ø32*3.0mm | height:15mm thickness:0.3-0.4mm |

ø32*3.0-0.62mm | |||

| Copper with aluminum | ø16*1.0mm | height:10mm thickness:0.3-0.4mm |

ø16*1.0-0.36mm | ||

| ø18*1.0mm | ø18*1.0-0.38mm | ||||

| ø22*1.0mm | ø22*1.0-0.46mm | ||||

| ø25*1.0mm | ø25*1.0-0.50mm | ||||

Our factory has over 20 years of experience as a manufacturer of ventilation and cooling equipment.

Professional Products:

1. We offer a range of professional products, including centrifugal fans, axial fans, duct fans, fan impellers, and mist fans.

2. We accommodate non-standard units and small orders.

3. Our accessories include forward impellers, backward impellers, axial impellers, and atomizers.

4. We specialize in ventilation and cooling solutions for industrial and commercial buildings.

Professional Manufacturing:

1. Our team of experienced engineers and R&D professionals supports product technology and development.

2. We have advanced manufacturing and inspection equipment, including laser cutting, CNC, dynamic balance, and product testing center.

3. Every product undergoes thorough inspection before delivery.

Professional Service:

1. Our products are exported to over 50 countries.

2. We prioritize on-time delivery.

3. All product have 3 years warranty.

4. Our experienced customer service team excels in communication, answering questions, and resolving issues.

Tags :

Hi! Click one of our members below to chat on