Buy Industrial Ventilation Fans Online

Buy Industrial Ventilation Fans Online

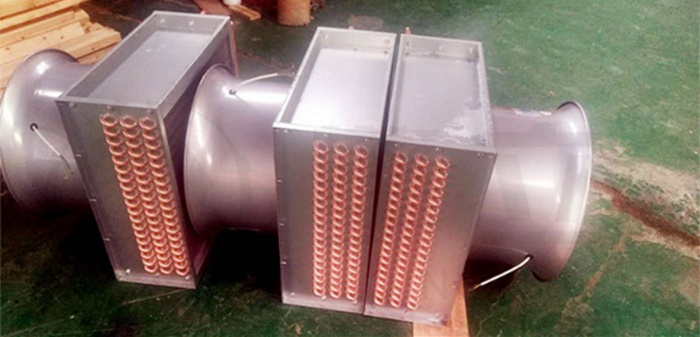

Stainless Steel Tube Heat Exchanger for Air Heating and Drying serves as an efficient air radiator for industrial heating and drying systems. Stainless Steel Tube Heat Exchanger for Air Heating and Dryingtransfers heat from steam, hot water, or thermal oil to air, providing stable performance and long service life. The compact structure allows easy integration into drying lines, ventilation systems, and other thermal processes.

Type :

Heat ExchangerPayment :

T/TOrder(MOQ) :

1 PCShipping Port :

GuangZhou, FoShanLead Time :

7-15 daysProduct Origin :

ChinaStainless Steel Tube Heat Exchanger for Air Heating and Drying

Stainless Steel Tube Heat Exchanger for Air Heating and Drying serves as an efficient air radiator for industrial heating and drying systems. Stainless Steel Tube Heat Exchanger for Air Heating and Dryingtransfers heat from steam, hot water, or thermal oil to air, providing stable performance and long service life. The compact structure allows easy integration into drying lines, ventilation systems, and other thermal processes.

Material Options

Available in multiple materials to match different working conditions:

Carbon steel

Stainless steel 304

Copper

Aluminum

Structure & Working Principle

1.The heat exchanger adopts seamless finned tubes to expand the heat transfer surface.

2.Compared with ordinary smooth tubes, finned tubes provide 5–10 times more heat exchange area, improving thermal efficiency and lowering operating costs.

The unit typically operates with steam pressure below 0.8 MPa and air outlet temperatures under 150°C, ensuring reliable heat transfer under standard industrial conditions.

Key Advantages

1.High heat transfer efficiency with finned tube construction

2.Durable structure with multiple corrosion-resistant materials

3.Compact design for easy maintenance and installation

4.Custom engineering service for non-standard systems

Customization & Technical Support

Custom-built solutions are available based on project drawings or specified parameters, including:

1.Airflow and inlet conditions.

2.Temperature and media requirements.

3.Dimensional and installation details.

4.Our engineering team provides complete technical guidance and performance optimization to ensure efficient and reliable operation.

| Material | Pipe | Fin | Fin-Pipe | ||

| Carbon steel | ø18*2.0mm | 10*0.3mm 12*0.3mm 15*0.3mm |

ø18*2.0-0.38mm | ||

| ø22*2.0mm | ø22*2.0-0.42mm | ø22*2.0-0.46mm | ø22*2.0-0.52mm | ||

| ø25*2.0mm | ø25*2.0-0.45mm | ø25*2.0-0.49mm | ø25*2.0-0.55mm | ||

| ø32*3.0mm | ø32*3.0-0.52mm | ø32*3.0-0.56mm | ø32*3.0-0.62mm | ||

| ø42*3.0mm | ø42*3.0-0.62mm | ø42*3.0-0.66mm | ø42*3.0-0.72mm | ||

| ø48*3.0mm | ø48*3.0-0.68mm | ø48*3.0-0.72mm | ø48*3.0-0.78mm | ||

| ø60*4.0mm | ø60*4.0-0.80mm | ø60*4.0-0.84mm | ø60*4.0-0.90mm | ||

| Stainless steel 304 | ø18*2.0mm | 10*0.3mm 12*0.3mm 15*0.4mm |

ø18*2.0-0.38mm | ||

| ø22*2.0mm | ø22*2.0-0.42mm | ø22*2.0-0.52mm | |||

| ø25*2.0mm | ø25*2.0-0.45mm | ø25*2.0-0.55mm | |||

| ø42*4.0mm | ø42*4.0-0.62mm | ø42*4.0-0.72mm | |||

| ø48*4.0mm | ø48*4.0-0.68mm | ø48*4.0-0.78mm | |||

| ø60*4.0mm | ø60*4.0-0.80mm | ø60*4.0-0.90mm | |||

| Carbon steel with aluminum | ø18*2.0mm | ø18*2.0-0.38mm | |||

| ø22*2.0mm | height:12mm thickness:0.3-0.4mm |

ø22*2.0-0.46mm | |||

| ø25*2.0mm | height:12.5mm thickness:0.3-0.4mm |

ø25*2.0-0.50mm | |||

| ø25*2.0mm | height:15mm thickness:0.3-0.4mm |

ø25*2.0-0.55mm | |||

| ø32*3.0mm | height:15mm thickness:0.3-0.4mm |

ø32*3.0-0.62mm | |||

| Copper with aluminum | ø16*1.0mm | height:10mm thickness:0.3-0.4mm |

ø16*1.0-0.36mm | ||

| ø18*1.0mm | ø18*1.0-0.38mm | ||||

| ø22*1.0mm | ø22*1.0-0.46mm | ||||

| ø25*1.0mm | ø25*1.0-0.50mm | ||||

Tags :

Hi! Click one of our members below to chat on