Buy Industrial Ventilation Fans Online

Buy Industrial Ventilation Fans Online

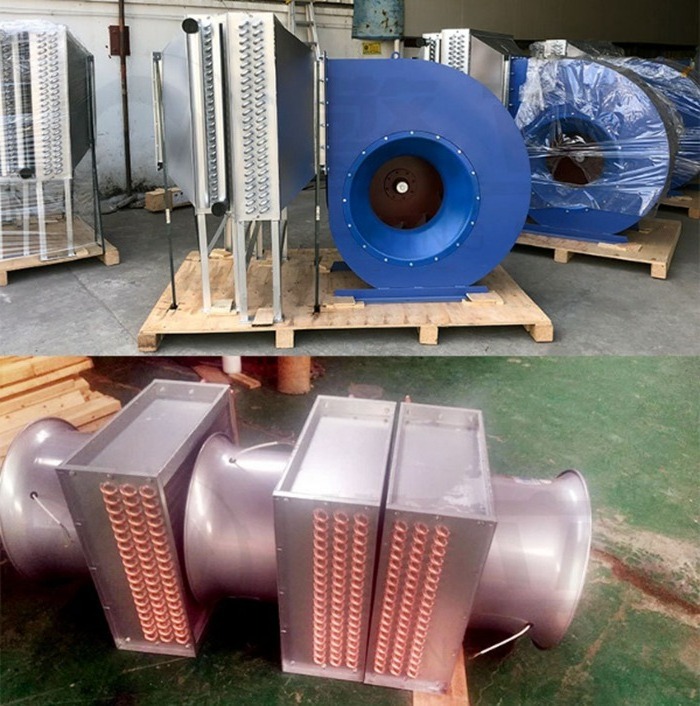

Flue Gas Boiler Heat Exchanger is an energy-efficient device designed to recover residual heat from industrial exhaust gases such as boiler flue gas, waste gas, and high-temperature air. It transfers heat from hot gases to cooler mediums (air or water), improving energy utilization, reducing emissions, and supporting green and sustainable industrial production.

Type :

Heat ExchangerPayment :

T/TOrder(MOQ) :

1 PCShipping Port :

GuangZhou, FoShanLead Time :

7-15 daysProduct Origin :

ChinaFlue Gas Boiler Heat Exchanger with Axial Flow Blower

Flue Gas Boiler Heat Exchanger primarily used to recover waste heat from flue gas for heating boiler feed water, domestic hot water, or air (for combustion support or material drying).A common heat exchange equipment in waste heat recovery systems for industrial boilers, aluminum smelting furnaces, and high-temperature air applications.

Benefit

1.High Efficiency & Energy Saving

Utilizes high-efficiency heat transfer elements to fully recover waste heat, directly reducing fuel consumption and operational costs.

2.Environmental Protection

Lowers flue gas emission temperature, reducing the release of greenhouse gases and waste heat into the environment.

3.Wide Applicability

Suitable for various industrial settings, including coal-fired, gas-fired, and oil-fired boilers, as well as applications like aluminum smelting furnaces and high-temperature hot air recovery.

4.Stable & Reliable

Robust construction with quality materials ensures long-term, stable operation even under demanding conditions like high temperatures.

Customization & Technical Support

We provide complete custom design and manufacturing services based on user requirements and project parameters.

1.Provide Drawings

Customers can send their design or equipment drawings to our technical team for quotation and scheme design.

2.Parameter Support

Please provide key parameters such as air volume, inlet conditions, dimensions, chilled water inlet temperature, and required outlet temperature for accurate design.

3.Technical Consultation

Our professional engineers offer technical consultation anytime—simply share your process parameters, and we’ll recommend the best configuration for your needs.

| Model LT- |

Model QLT- |

heat dissipation area(m2) | Size(mm) | Front area(m2) | Rows | Fin number | ||

| L | W | H | ||||||

| 2R-12-24 | 2x12x6 | 10.92 | 610 | 542 | 130 | 0.279 | 2 | 12 |

| 2R-12-30 | 2x12x7 | 14.25 | 760 | 542 | 130 | 0.279 | 2 | 12 |

| 2R-12-48 | 2x12x12 | 21.84 | 1220 | 542 | 130 | 0.279 | 2 | 12 |

| 4R-12-42 | 4x12x10 | 56.19 | 1070 | 542 | 190 | 0.279 | 4 | 12 |

| 4R-18-30 | 4x18x7 | 43.06 | 760 | 782 | 190 | 0.418 | 4 | 18 |

| 4R-12-54 | 4x12x13 | 51.17 | 1370 | 542 | 190 | 0.279 | 4 | 12 |

| 8R-18-24 | 8x18x6 | 65.52 | 610 | 782 | 330 | 0.418 | 8 | 18 |

| 6R-15-42 | 6x15x10 | 72.38 | 1070 | 662 | 260 | 0.342 | 6 | 15 |

| 6R-12-60 | 6x15x15 | 86.11 | 1520 | 542 | 260 | 0.279 | 6 | 12 |

| 6R-18-48 | 6x18x12 | 98.23 | 1220 | 782 | 260 | 0.418 | 6 | 18 |

| 6R-18-54 | 6x18x13 | 115.14 | 1370 | 782 | 260 | 0.418 | 6 | 18 |

Working Principle

The equipment operates on the principle of flue gas hydrothermal/heat transfer. High-temperature flue gas passes through the exchanger, transferring its heat to a cooler medium (such as water or air). This process heats the medium while significantly cooling the flue gas, effectively reclaiming heat that would otherwise be wasted.

Material Options

Available in several materials including Carbon Steel, Stainless Steel 304, Copper, and Aluminum to suit different operational conditions and media requirements, ensuring corrosion resistance and longevity.

Our factory has over 20 years of experience as a manufacturer of ventilation and cooling equipment.

Professional Products:

1.We provide professional products: centrifugal fans, axial fans, duct fans, fan impellers, and mist fans.

2.We accept non-standard units and small orders.

3.Our accessories cover forward/backward/axial impellers and atomizers.

4.We specialize in industrial and commercial ventilation & cooling solutions.

Professional Manufacturing:

1.Experienced engineers and R&D teams support product technology and development.

2.We have advanced manufacturing/inspection equipment: laser cutting, CNC, dynamic balance, and product testing center.

3.Every product is thoroughly inspected prior to delivery.

Professional Service:

1.Our products are exported to over 50 countries.

2.We prioritize on-time delivery.

3.All products come with a 3-year warranty.

4.Our experienced customer service team excels in communication, answering questions and resolving issues.

Tags :

Hi! Click one of our members below to chat on