Buy Industrial Ventilation Fans Online

Buy Industrial Ventilation Fans Online

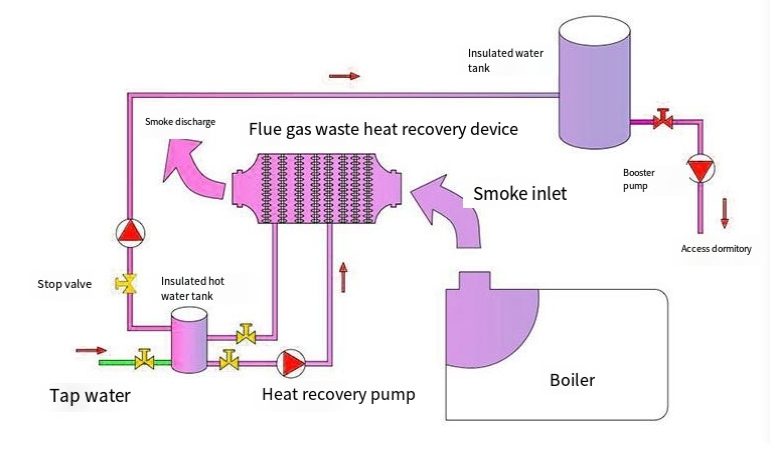

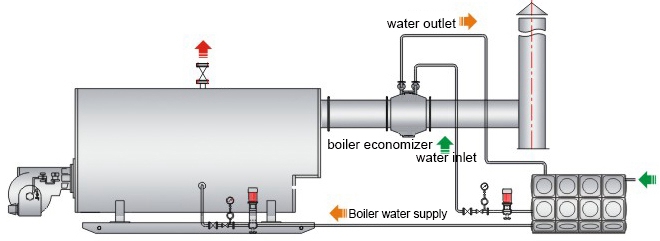

Waste Heat Recovery Boiler Exhaust Heat Exchanger is a professional industrial device. It recovers waste heat from high-temperature flue gas via efficient heat exchange, lowering flue gas temperature, cutting energy use, and boosting boiler thermal efficiency. This system is widely used for boiler, aluminum smelting furnace, and high-temperature hot air waste heat recovery, serving as a reliable Flue Gas Tailpipe Cooler.

Type :

Heat ExchangerPayment :

T/TOrder(MOQ) :

1 PCShipping Port :

GuangZhou, FoShanLead Time :

7-15 daysProduct Origin :

ChinaWaste Heat Recovery Boiler Exhaust Heat Exchanger

Waste Heat Recovery Boiler Exhaust Heat Exchanger is a professional industrial device. It recovers waste heat from high-temperature flue gas via efficient heat exchange, lowering flue gas temperature, cutting energy use, and boosting boiler thermal efficiency. This system is widely used for boiler, aluminum smelting furnace, and high-temperature hot air waste heat recovery, serving as a reliable Flue Gas Tailpipe Cooler.

Key Advantages

1.Energy Savings:Recovers waste heat to improve boiler thermal efficiency, reducing fuel consumption and energy costs.

2.Durability:Features a seamless heat transfer element with high-pressure resistance (up to 2.2 MPa) and corrosion-resistant materials, ensuring a long service life exceeding 10 years.

3.Reduced Environmental Impact:Lowers flue gas temperature and cuts greenhouse gas emissions by minimizing fuel use.

4.Low Maintenance:Designed with an even internal flow field to prevent dew-point corrosion and scaling.

5.Easy Installation:modular design allows installation without altering existing boiler systems.

Function

Recovers boiler exhaust waste heat to heat low-temperature media (water/air), achieving energy saving and flue gas cooling.

Application Scope

Boiler flue gas, aluminum smelting furnace flue gas, high-temperature hot air waste heat recovery; compatible with air/water/oil boilers and steam heating systems.

Working Principle

Boiler Exhaust Heat Exchanger uses efficient heat exchange technology to transfer heat from high-temperature flue gas to target media, maximizing waste heat use.

Optional Materials:

Carbon steel, stainless steel 304, copper, aluminum.

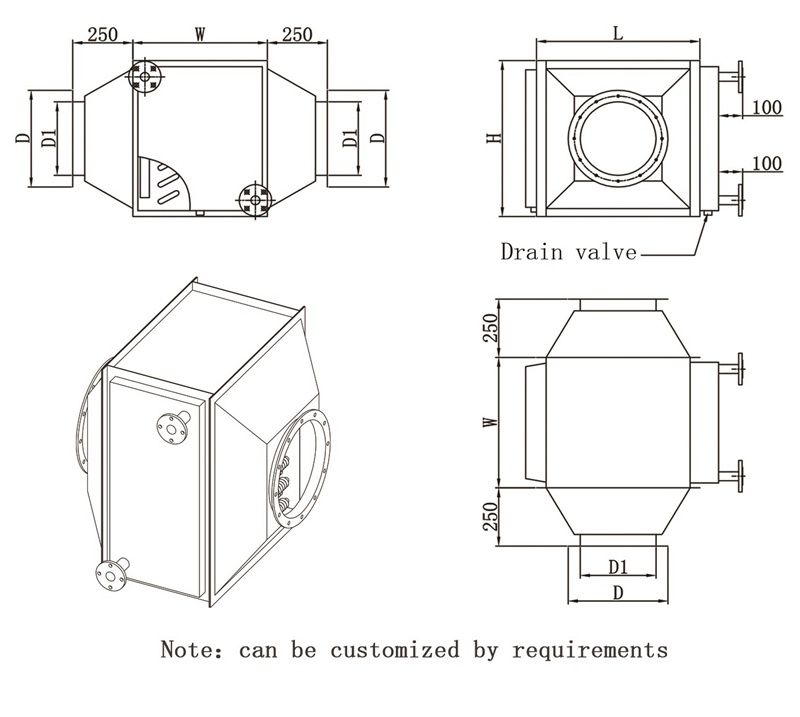

| Number | Flue gas volume (m³/h) |

Flue gas temperature drop(℃) |

Water flow (T/h) |

L (mm) |

H (mm) |

W (mm) |

D (mm) |

D1 (mm) |

interface | Recovery of heat (kW) |

Saving natural gas (m³/h) |

| 1 | ≤970 | 280℃-130℃ | 1 | 480 | 530 | 580 | 380 | 300 | DN25 | 50 | 5.4 |

| 2 | ≤1463 | 280℃-130℃ | 1.5 | 580 | 530 | 580 | 380 | 300 | DN32 | 75 | 8 |

| 3 | ≤1950 | 280℃→130℃ | 2 | 680 | 670 | 580 | 480 | 400 | DN32 | 100 | 10.8 |

| 4 | ≤2925 | 280℃-130℃ | 3 | 780 | 810 | 580 | 480 | 400 | DN40 | 150 | 16 |

| 5 | ≤3900 | 280℃→130℃ | 4 | 880 | 950 | 580 | 580 | 500 | DN40 | 200 | 21.5 |

| 6 | ≤4225 | 280℃-130℃ | 5 | 980 | 950 | 600 | 580 | 500 | DN50 | 215 | 23 |

| 7 | ≤5444 | 280℃-130℃ | 6 | 980 | 1020 | 600 | 680 | 600 | DN50 | 275 | 29.6 |

| 8 | ≤7259 | 280℃-130℃ | 8 | 1080 | 1160 | 600 | 780 | 700 | DN50 | 365 | 39 |

| 9 | ≤9073 | 280℃-130℃ | 10 | 1280 | 1230 | 600 | 880 | 800 | DN50 | 455 | 49 |

| 10 | ≤10888 | 280℃-130℃ | 12 | 1380 | 1370 | 600 | 980 | 900 | DN50 | 550 | 59 |

Customization Services

We provide comprehensive customized design servicesto ensure the heat exchanger perfectly fits your specific operational requirements and spatial constraints.

You can share your design drawings or key parameters (e.g., flue gas volume, inlet/outlet temperatures, pressure rating, space limitations), and our technical team will develop a tailored solution and quotation .

We adapt the size, materials, connection ports, and performance parametersbased on your needs. Additionally, we offer expert technical consultation throughout the process, from initial assessment to operational optimizations.

| Material | Pipe | Fin | Fin-Pipe | ||

| Carbon steel | ø18*2.0mm | 10*0.3mm 12*0.3mm 15*0.3mm |

ø18*2.0-0.38mm | ||

| ø22*2.0mm | ø22*2.0-0.42mm | ø22*2.0-0.46mm | ø22*2.0-0.52mm | ||

| ø25*2.0mm | ø25*2.0-0.45mm | ø25*2.0-0.49mm | ø25*2.0-0.55mm | ||

| ø32*3.0mm | ø32*3.0-0.52mm | ø32*3.0-0.56mm | ø32*3.0-0.62mm | ||

| ø42*3.0mm | ø42*3.0-0.62mm | ø42*3.0-0.66mm | ø42*3.0-0.72mm | ||

| ø48*3.0mm | ø48*3.0-0.68mm | ø48*3.0-0.72mm | ø48*3.0-0.78mm | ||

| ø60*4.0mm | ø60*4.0-0.80mm | ø60*4.0-0.84mm | ø60*4.0-0.90mm | ||

| Stainless steel 304 | ø18*2.0mm | 10*0.3mm 12*0.3mm 15*0.4mm |

ø18*2.0-0.38mm | ||

| ø22*2.0mm | ø22*2.0-0.42mm | ø22*2.0-0.52mm | |||

| ø25*2.0mm | ø25*2.0-0.45mm | ø25*2.0-0.55mm | |||

| ø42*4.0mm | ø42*4.0-0.62mm | ø42*4.0-0.72mm | |||

| ø48*4.0mm | ø48*4.0-0.68mm | ø48*4.0-0.78mm | |||

| ø60*4.0mm | ø60*4.0-0.80mm | ø60*4.0-0.90mm | |||

| Carbon steel with aluminum | ø18*2.0mm | ø18*2.0-0.38mm | |||

| ø22*2.0mm | height:12mm thickness:0.3-0.4mm |

ø22*2.0-0.46mm | |||

| ø25*2.0mm | height:12.5mm thickness:0.3-0.4mm |

ø25*2.0-0.50mm | |||

| ø25*2.0mm | height:15mm thickness:0.3-0.4mm |

ø25*2.0-0.55mm | |||

| ø32*3.0mm | height:15mm thickness:0.3-0.4mm |

ø32*3.0-0.62mm | |||

| Copper with aluminum | ø16*1.0mm | height:10mm thickness:0.3-0.4mm |

ø16*1.0-0.36mm | ||

| ø18*1.0mm | ø18*1.0-0.38mm | ||||

| ø22*1.0mm | ø22*1.0-0.46mm | ||||

| ø25*1.0mm | ø25*1.0-0.50mm | ||||

Tags :

Hi! Click one of our members below to chat on