Buy Industrial Ventilation Fans Online

Buy Industrial Ventilation Fans Online

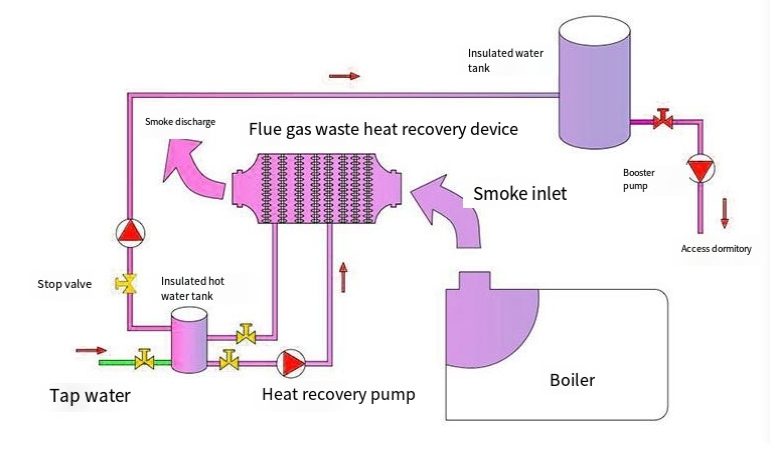

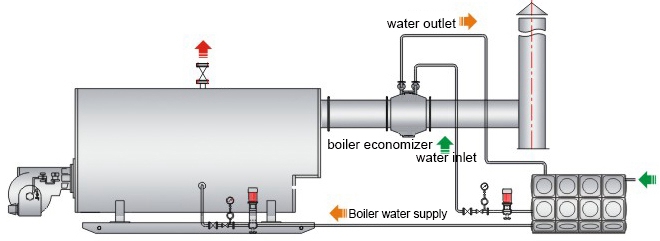

Flue Gas to Water Heat Exchanger recovers heat from high-temperature exhaust gas and transfers it to water or air. Flue Gas to Water Heat Exchanger lowers flue gas temperature, improves boiler efficiency, and reduces fuel costs. Commonly used in boilers, aluminum furnaces, and high-temperature drying systems.

Type :

Heat ExchangerPayment :

T/TOrder(MOQ) :

1 PCShipping Port :

GuangZhou, FoShanLead Time :

7-15 daysProduct Origin :

ChinaFlue Gas to Water Heat Exchanger

Flue Gas to Water Heat Exchanger recovers heat from high-temperature exhaust gas and transfers it to water or air. Flue Gas to Water Heat Exchanger lowers flue gas temperature, improves boiler efficiency, and reduces fuel costs. Commonly used in boilers, aluminum furnaces, and high-temperature drying systems.

Key Benefits

1.Energy Saving: Reuses waste heat to cut fuel consumption.

2.Durable: Seamless heat transfer structure, pressure-resistant up to 2.2 MPa, and corrosion-proof materials for long service life.

3.Eco-Friendly: Reduces emissions by improving energy utilization.

4.Low Maintenance: Stable flow design prevents corrosion and scaling.

5.Easy Setup: Modular design fits existing systems.

How It Works

Heat from flue gas is transferred to low-temperature media through efficient heat exchange surfaces, achieving continuous heat recovery and cooling of exhaust gases.

Material Options

Carbon Steel | Stainless Steel 304 | Copper | Aluminum

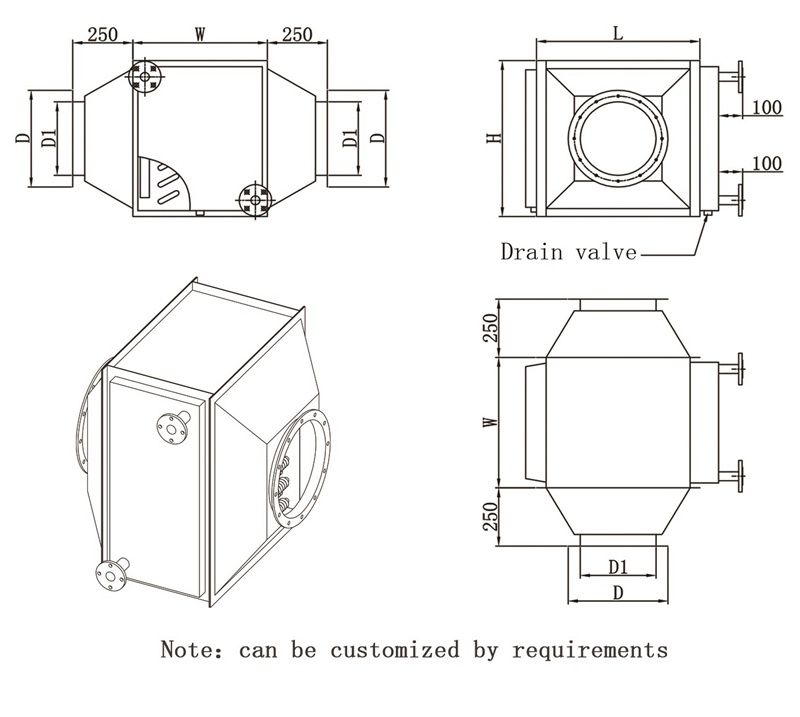

| Number | Flue gas volume (m³/h) |

Flue gas temperature drop(℃) |

Water flow (T/h) |

L (mm) |

H (mm) |

W (mm) |

D (mm) |

D1 (mm) |

interface | Recovery of heat (kW) |

Saving natural gas (m³/h) |

| 1 | ≤970 | 280℃-130℃ | 1 | 480 | 530 | 580 | 380 | 300 | DN25 | 50 | 5.4 |

| 2 | ≤1463 | 280℃-130℃ | 1.5 | 580 | 530 | 580 | 380 | 300 | DN32 | 75 | 8 |

| 3 | ≤1950 | 280℃→130℃ | 2 | 680 | 670 | 580 | 480 | 400 | DN32 | 100 | 10.8 |

| 4 | ≤2925 | 280℃-130℃ | 3 | 780 | 810 | 580 | 480 | 400 | DN40 | 150 | 16 |

| 5 | ≤3900 | 280℃→130℃ | 4 | 880 | 950 | 580 | 580 | 500 | DN40 | 200 | 21.5 |

| 6 | ≤4225 | 280℃-130℃ | 5 | 980 | 950 | 600 | 580 | 500 | DN50 | 215 | 23 |

| 7 | ≤5444 | 280℃-130℃ | 6 | 980 | 1020 | 600 | 680 | 600 | DN50 | 275 | 29.6 |

| 8 | ≤7259 | 280℃-130℃ | 8 | 1080 | 1160 | 600 | 780 | 700 | DN50 | 365 | 39 |

| 9 | ≤9073 | 280℃-130℃ | 10 | 1280 | 1230 | 600 | 880 | 800 | DN50 | 455 | 49 |

| 10 | ≤10888 | 280℃-130℃ | 12 | 1380 | 1370 | 600 | 980 | 900 | DN50 | 550 | 59 |

Custom Service

Customized units are available based on drawings or parameters such as flue gas flow, temperature, and installation size.

Our engineers provide full technical support and optimized solutions for stable, efficient operation.

| Material | Pipe | Fin | Fin-Pipe | ||

| Carbon steel | ø18*2.0mm | 10*0.3mm 12*0.3mm 15*0.3mm |

ø18*2.0-0.38mm | ||

| ø22*2.0mm | ø22*2.0-0.42mm | ø22*2.0-0.46mm | ø22*2.0-0.52mm | ||

| ø25*2.0mm | ø25*2.0-0.45mm | ø25*2.0-0.49mm | ø25*2.0-0.55mm | ||

| ø32*3.0mm | ø32*3.0-0.52mm | ø32*3.0-0.56mm | ø32*3.0-0.62mm | ||

| ø42*3.0mm | ø42*3.0-0.62mm | ø42*3.0-0.66mm | ø42*3.0-0.72mm | ||

| ø48*3.0mm | ø48*3.0-0.68mm | ø48*3.0-0.72mm | ø48*3.0-0.78mm | ||

| ø60*4.0mm | ø60*4.0-0.80mm | ø60*4.0-0.84mm | ø60*4.0-0.90mm | ||

| Stainless steel 304 | ø18*2.0mm | 10*0.3mm 12*0.3mm 15*0.4mm |

ø18*2.0-0.38mm | ||

| ø22*2.0mm | ø22*2.0-0.42mm | ø22*2.0-0.52mm | |||

| ø25*2.0mm | ø25*2.0-0.45mm | ø25*2.0-0.55mm | |||

| ø42*4.0mm | ø42*4.0-0.62mm | ø42*4.0-0.72mm | |||

| ø48*4.0mm | ø48*4.0-0.68mm | ø48*4.0-0.78mm | |||

| ø60*4.0mm | ø60*4.0-0.80mm | ø60*4.0-0.90mm | |||

| Carbon steel with aluminum | ø18*2.0mm | ø18*2.0-0.38mm | |||

| ø22*2.0mm | height:12mm thickness:0.3-0.4mm |

ø22*2.0-0.46mm | |||

| ø25*2.0mm | height:12.5mm thickness:0.3-0.4mm |

ø25*2.0-0.50mm | |||

| ø25*2.0mm | height:15mm thickness:0.3-0.4mm |

ø25*2.0-0.55mm | |||

| ø32*3.0mm | height:15mm thickness:0.3-0.4mm |

ø32*3.0-0.62mm | |||

| Copper with aluminum | ø16*1.0mm | height:10mm thickness:0.3-0.4mm |

ø16*1.0-0.36mm | ||

| ø18*1.0mm | ø18*1.0-0.38mm | ||||

| ø22*1.0mm | ø22*1.0-0.46mm | ||||

| ø25*1.0mm | ø25*1.0-0.50mm | ||||

Professional Products

1.We supply a full range of centrifugal fans, axial fans, duct fans, fan impellers, and mist fans for industrial and commercial applications.

2.Non-standard customization and small-batch production are available to meet specific project needs.

3.Accessories include forward-curved, backward-curved, and axial impellers, as well as atomizers for cooling systems.

4.Our products deliver reliable ventilation and cooling performance across factories, workshops, and building systems.

Professional Manufacturing

1.Our engineering and R&D teams provide solid technical support and continuous product innovation.

2.Production is backed by advanced facilities, including laser cutting, CNC machining, dynamic balancing, and a comprehensive testing center.

3.Every unit undergoes strict inspection to ensure performance stability and long-term reliability before shipment.

Professional Service

1.Our products are exported to over 50 countries worldwide with on-time delivery and full logistics support.

2.All items include a three-year warranty for quality assurance.

3.A responsive and experienced service team ensures smooth communication and efficient problem-solving throughout the order process.

Tags :

Hi! Click one of our members below to chat on