Buy Industrial Ventilation Fans Online

Buy Industrial Ventilation Fans Online

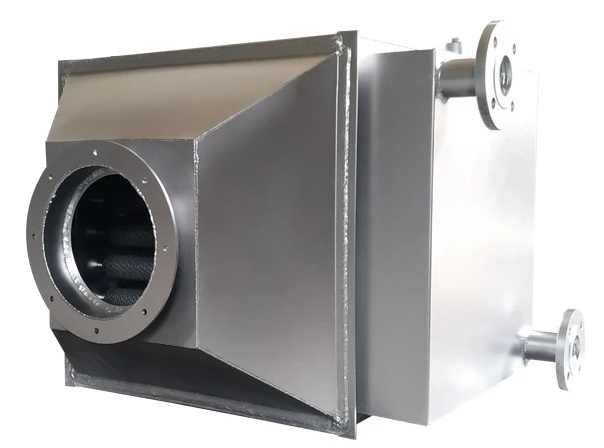

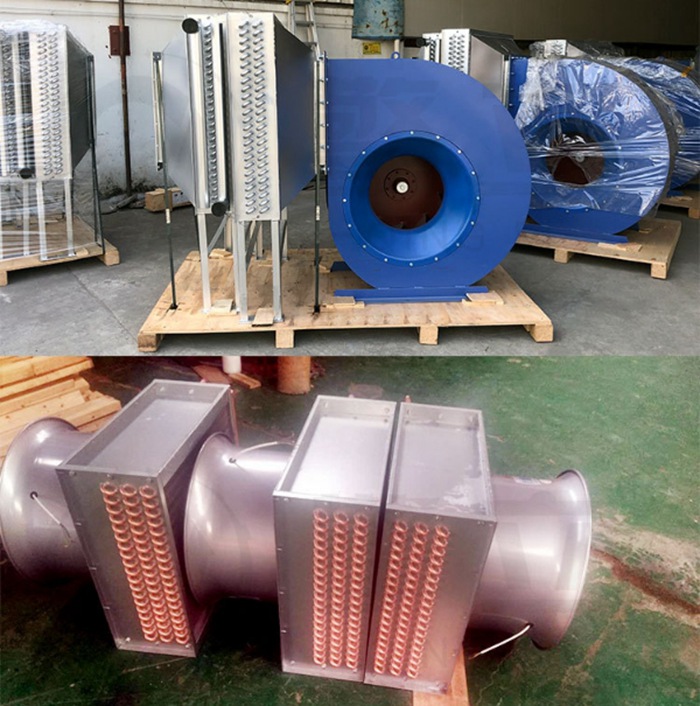

Waste Heat Boiler High Temperature Heat Exchanger recovers heat from industrial flue gas, exhaust gas, or wastewater and transfers it to air, water, or process fluids. This recovery process lowers exhaust temperatures, reduces fuel usage, and increases overall energy efficiency across heating, drying, and production systems.

Type :

Heat ExchangerPayment :

T/TOrder(MOQ) :

1 PCShipping Port :

GuangZhou, FoShanLead Time :

7-15 daysProduct Origin :

ChinaWaste Heat Boiler High Temperature Heat Exchanger

Waste Heat Boiler High Temperature Heat Exchanger recovers heat from industrial flue gas, exhaust gas, or wastewater and transfers it to air, water, or process fluids. This recovery process lowers exhaust temperatures, reduces fuel usage, and increases overall energy efficiency across heating, drying, and production systems.

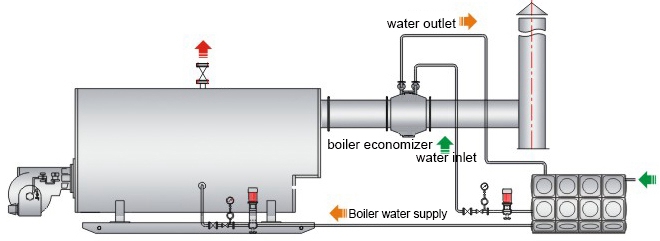

Application

1.Boiler flue gas and exhaust heat recovery.

2.Aluminum smelting furnaces and high-temperature kilns.

3.Hot-air drying, air preheating, and process heating systems.

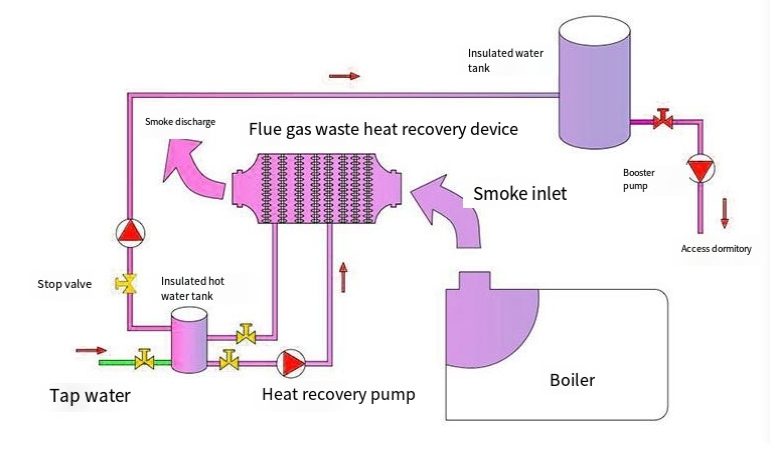

Working Principle

Heat from high-temperature exhaust is transferred to lower-temperature media through heat exchange surfaces. The process minimizes heat loss, improves boiler performance, and supports sustainable energy utilization.

Material Options

To meet different operating environments and temperature ranges, several material configurations are available:

1.Stainless Steel 304 – excellent corrosion and temperature resistance

2.Copper – high thermal conductivity for efficient heat exchange

3.Aluminum – lightweight with good heat transfer performance

4.Carbon Steel – cost-effective for standard industrial use

Key Benefits

High heat transfer efficiency for maximum energy recovery

eduction in fuel consumption and operating costs

Adaptable to various industrial heating and exhaust processes

Built with corrosion-resistant materials for long-term reliability

Helps meet environmental and emission control requirements

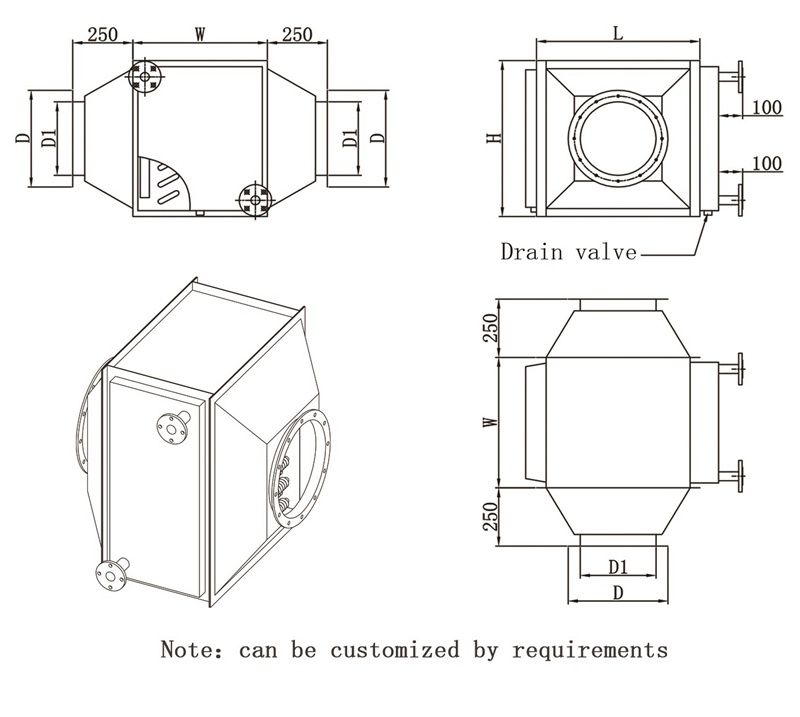

| Number | Flue gas volume (m³/h) |

Flue gas temperature drop(℃) |

Water flow (T/h) |

L (mm) |

H (mm) |

W (mm) |

D (mm) |

D1 (mm) |

interface | Recovery of heat (kW) |

Saving natural gas (m³/h) |

| 1 | ≤970 | 280℃-130℃ | 1 | 480 | 530 | 580 | 380 | 300 | DN25 | 50 | 5.4 |

| 2 | ≤1463 | 280℃-130℃ | 1.5 | 580 | 530 | 580 | 380 | 300 | DN32 | 75 | 8 |

| 3 | ≤1950 | 280℃→130℃ | 2 | 680 | 670 | 580 | 480 | 400 | DN32 | 100 | 10.8 |

| 4 | ≤2925 | 280℃-130℃ | 3 | 780 | 810 | 580 | 480 | 400 | DN40 | 150 | 16 |

| 5 | ≤3900 | 280℃→130℃ | 4 | 880 | 950 | 580 | 580 | 500 | DN40 | 200 | 21.5 |

| 6 | ≤4225 | 280℃-130℃ | 5 | 980 | 950 | 600 | 580 | 500 | DN50 | 215 | 23 |

| 7 | ≤5444 | 280℃-130℃ | 6 | 980 | 1020 | 600 | 680 | 600 | DN50 | 275 | 29.6 |

| 8 | ≤7259 | 280℃-130℃ | 8 | 1080 | 1160 | 600 | 780 | 700 | DN50 | 365 | 39 |

| 9 | ≤9073 | 280℃-130℃ | 10 | 1280 | 1230 | 600 | 880 | 800 | DN50 | 455 | 49 |

| 10 | ≤10888 | 280℃-130℃ | 12 | 1380 | 1370 | 600 | 980 | 900 | DN50 | 550 | 59 |

Customization & Technical Support

Units can be manufactured according to customer drawings or process requirements. Parameters such as airflow, temperature, media type, and dimensions can be customized.

Our engineering team provides full technical assistance — from selection and design optimization to on-site application guidance — ensuring each exchanger delivers reliable and efficient operation.

| Material | Pipe | Fin | Fin-Pipe | ||

| Carbon steel | ø18*2.0mm | 10*0.3mm 12*0.3mm 15*0.3mm |

ø18*2.0-0.38mm | ||

| ø22*2.0mm | ø22*2.0-0.42mm | ø22*2.0-0.46mm | ø22*2.0-0.52mm | ||

| ø25*2.0mm | ø25*2.0-0.45mm | ø25*2.0-0.49mm | ø25*2.0-0.55mm | ||

| ø32*3.0mm | ø32*3.0-0.52mm | ø32*3.0-0.56mm | ø32*3.0-0.62mm | ||

| ø42*3.0mm | ø42*3.0-0.62mm | ø42*3.0-0.66mm | ø42*3.0-0.72mm | ||

| ø48*3.0mm | ø48*3.0-0.68mm | ø48*3.0-0.72mm | ø48*3.0-0.78mm | ||

| ø60*4.0mm | ø60*4.0-0.80mm | ø60*4.0-0.84mm | ø60*4.0-0.90mm | ||

| Stainless steel 304 | ø18*2.0mm | 10*0.3mm 12*0.3mm 15*0.4mm |

ø18*2.0-0.38mm | ||

| ø22*2.0mm | ø22*2.0-0.42mm | ø22*2.0-0.52mm | |||

| ø25*2.0mm | ø25*2.0-0.45mm | ø25*2.0-0.55mm | |||

| ø42*4.0mm | ø42*4.0-0.62mm | ø42*4.0-0.72mm | |||

| ø48*4.0mm | ø48*4.0-0.68mm | ø48*4.0-0.78mm | |||

| ø60*4.0mm | ø60*4.0-0.80mm | ø60*4.0-0.90mm | |||

| Carbon steel with aluminum | ø18*2.0mm | ø18*2.0-0.38mm | |||

| ø22*2.0mm | height:12mm thickness:0.3-0.4mm |

ø22*2.0-0.46mm | |||

| ø25*2.0mm | height:12.5mm thickness:0.3-0.4mm |

ø25*2.0-0.50mm | |||

| ø25*2.0mm | height:15mm thickness:0.3-0.4mm |

ø25*2.0-0.55mm | |||

| ø32*3.0mm | height:15mm thickness:0.3-0.4mm |

ø32*3.0-0.62mm | |||

| Copper with aluminum | ø16*1.0mm | height:10mm thickness:0.3-0.4mm |

ø16*1.0-0.36mm | ||

| ø18*1.0mm | ø18*1.0-0.38mm | ||||

| ø22*1.0mm | ø22*1.0-0.46mm | ||||

| ø25*1.0mm | ø25*1.0-0.50mm | ||||

Our factory has over 20 years of experience as a manufacturer of ventilation and cooling equipment.

Professional Products:

1. We offer a range of professional products, including centrifugal fans, axial fans, duct fans, fan impellers, and mist fans.

2. We accommodate non-standard units and small orders.

3. Our accessories include forward impellers, backward impellers, axial impellers, and atomizers.

4. We specialize in ventilation and cooling solutions for industrial and commercial buildings.

Professional Manufacturing:

1. Our team of experienced engineers and R&D professionals supports product technology and development.

2. We have advanced manufacturing and inspection equipment, including laser cutting, CNC, dynamic balance, and product testing center.

3. Every product undergoes thorough inspection before delivery.

Professional Service:

1. Our products are exported to over 50 countries.

2. We prioritize on-time delivery.

3. All product have 3 years warranty.

4. Our experienced customer service team excels in communication, answering questions, and resolving issues.

Tags :

Hi! Click one of our members below to chat on