Buy Industrial Ventilation Fans Online

Buy Industrial Ventilation Fans Online

304 Stainless Steel Food Grade Plate Liquid Heat Exchanger 5 Square Meter Plate Heat Exchanger Customized

Type :

Heat ExchangerPayment :

T/TOrder(MOQ) :

1 PCShipping Port :

GuangZhou, FoShanLead Time :

7-15 daysProduct Origin :

China304 Stainless Steel Food Grade Plate Liquid Heat Exchanger 5 Square Meter Plate Heat Exchanger Customized

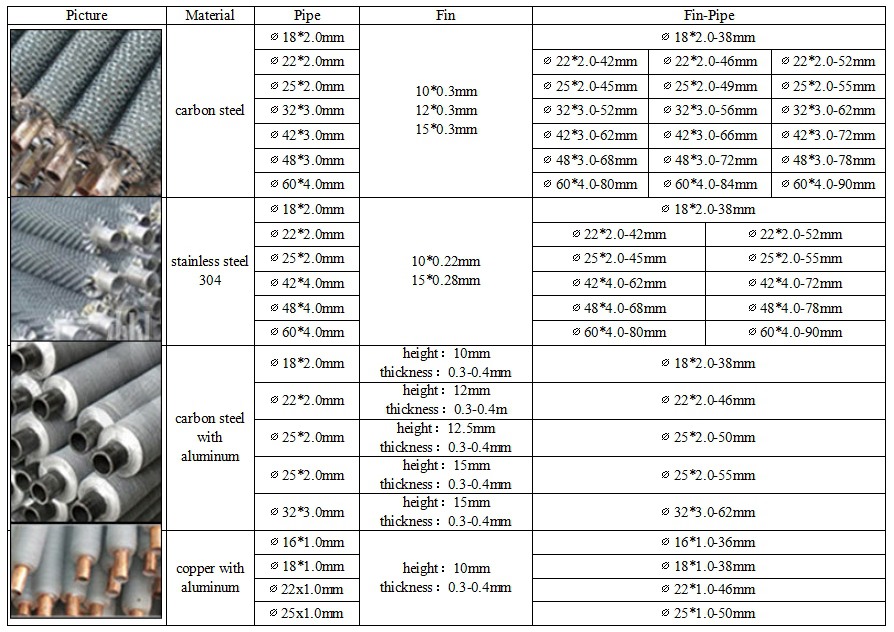

several material available:

carbon steel, stainless steel 304, copper, aluminum

Plate heat exchanger

It is a new type of high efficiency heat exchanger composed of a series of metal sheets with a certain corrugated shape. Thin rectangular channels are formed between various plates, through which heat is exchanged. Plate heat exchanger is the ideal equipment for liquid - liquid, liquid - steam heat exchange. It has the characteristics of high heat exchange efficiency, small heat loss, compact and lightweight structure, small footprint, convenient installation and cleaning, wide application, long service life and so on. In the case of the same pressure loss, its heat transfer coefficient is 3-5 times higher than the tube heat exchanger, the floor area is one-third of the tube heat exchanger, and the heat recovery rate can be as high as 90%. There are three main types of plate forms: human-shaped corrugated plate, horizontal corrugated plate and nodular plate.

product feature

1, high efficiency and energy saving: its heat transfer coefficient is 3000 ~ 4500kcal/m2·°C·h, which is 3~5 times higher than the thermal efficiency of tube and shell heat exchanger.

2, compact structure: plate heat exchanger plates are closely arranged, compared with other heat exchanger types, plate heat exchanger covers an area and occupies less space, and the plate heat exchanger with the same area is only 1/5 of the shell and tube heat exchanger.

3, easy to clean and disassemble convenient: plate heat exchanger clamping bolt clamping plate, so convenient disassembly, can be opened at any time cleaning, at the same time due to the smooth surface, high degree of turbulence, not easy to scale.

4, long service life: plate heat exchanger is pressed by stainless steel or titanium alloy plate, can resist various corrosive media, rubber pad can be replaced at will, and can be convenient in, disassembly and maintenance.

5, strong adaptability: plate heat exchanger plates are independent components, can be arbitrarily increased or decreased according to requirements, various forms; Can be applied to a variety of different process requirements.

6, do not string liquid, plate heat exchanger sealed groove set up the drain liquid channel, various media will not collude.

applied range

Plate heat exchanger has been widely used in metallurgy, mining, petroleum, chemical industry, electric power, medicine, food, chemical fiber, paper, textile, shipbuilding, heating and other departments, can be used for heating, cooling, evaporation, condensation, sterilization, waste heat recovery and other situations.

| plate material | |

| material | suitable liquid |

| stainless steel SU304 SUS316 SUS316L SUS321 SUS310S SUS317L |

General fluid with low chloride content |

| industrial pure titanium TA1 | liquid with a high chloride content, such as seawater |

| hastelloy | Chlorinated acids, such as sulfuric acid, mixed acids |

| acid-resisting steel RS-2 | Strong acids, such as concentrated sulfuric acid, nitric acid, etc |

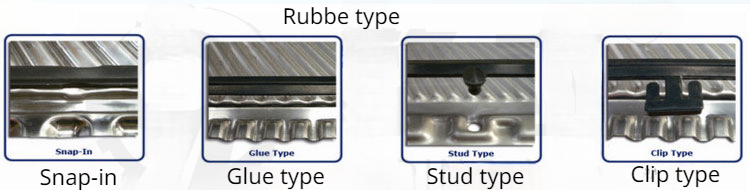

| Rubber materials | ||

| materials | operating temperature | suitable medium |

| epdm rubber E | -50℃~150℃ | Water, general organic and inorganic acids, alkali and chemical media |

| nitrile rubber N | -20℃~110℃ | Water, oil, hydrocarbon, aldehydes and general corrosive media |

| Food, medicine rubber S | -20℃~120℃ | Food materials, pharmaceutical industry materials |

| fluororubber F | 0℃~180℃ | Organic solutions, acids, bases, alcohols, oils |

| chloroprene rubber U | -40℃~100℃ | Bases and some acids |

| silicone rubber Q | -65℃~230℃ | Some oils, alcohol |

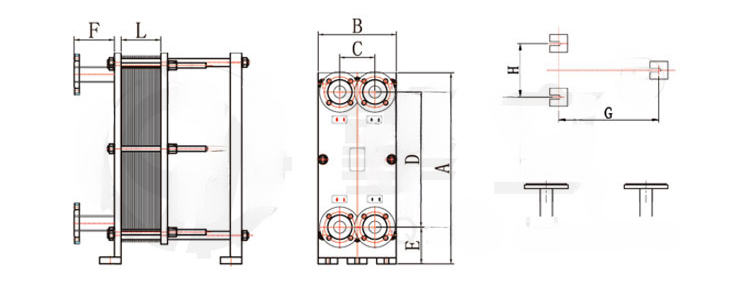

| Specification | ||||||||||||

| Model | BR006 | BR012 | BR15 | BR025 | BR28 | BR03 | BR035 | BR04 | BR45 | BR065 | BR09 | BR13 |

| Pressure MPa | 2.0 | |||||||||||

| Temperature ℃ | -19~200 | |||||||||||

| Area m² | 0.5-5 | 1-10 | 3-20 | 3-30 | 10-60 | 15-45 | 15-60 | 20-100 | 30-140 | 50-200 | 60-250 | 90-650 |

| Flow liquid(gas) m³/h | 30 (300) |

70 (700) |

80 (800) |

100 (1000) |

180 (1800) |

200 (2000) |

200 (2000) |

250 (2500) |

300 (3000) |

300 (3000) |

600 (6000) |

1200 (12000) |

| Heat transfer coefficient (water-water)w/m² k | ≤6000 | |||||||||||

| Maximum heat exchange (water-water) |

0.6 | 1 | 60 | 6 | 80 | 90 | 16 | 120 | 30 | 35 | 50 | 90 |

| Diameter mm | 40 | 50 | 50 | 65 | 100 | 100 | 100 | 100 | 150 | 150 | 175 | 250 |

| Weight kg | 70 | 280 | 350 | 590 | 600 | 1500 | 1450 | 2500 | 2520 | 2700 | 4980 | 9800 |

| Dimension | ||||||||||||

| Model | BR006 | BR012 | BR15 | BR025 | BR28 | BR03 | BR035 | BR04 | BR045 | BR065 | BR09 | BR13 |

| A | 580 | 735 | 870 | 1110 | 1084 | 1148 | 1315 | 1326 | 1555 | 1690 | 2125 | 2750 |

| B | 228 | 320 | 320 | 425 | 470 | 460 | 485 | 480 | 600 | 640 | 760 | 980 |

| C | 94 | 144 | 140 | 200 | 223 | 223 | 220 | 225 | 264 | 284 | 383 | 498 |

| 0 | 420 | 554 | 640 | 867 | 719 | 846 | 1040 | 1046 | 1232 | 1355 | 1524 | 1820 |

| E | 105 | 116 | 150 | 160 | 210 | 190 | 190 | 160 | 290 | 270 | 310 | 490 |

| F | L+120 | L+400 | L+450 | L+500 | L+500 | L+600 | L+600 | L+600 | L+700 | L+700 | L+800 | L+1200 |

| G | F | F-65 | F-97 | F-100 | F-100 | F-30 | F-100 | F-100 | F | F | F-95 | F |

| H | 178 | 240 | 240 | 290 | 370 | 340 | 370 | 388 | 500 | 510 | 640 | 870 |

| L | 3.6N | 3.9N | 3.8N | 4.1N | 4.6N | 4.6N | 4.2N | 4.2N | 4.5N | 4.5N | 4.5N | 4.5N |

| Diameter | 40 | 50 | 50 | 65 | 100 | 100 | 100 | 100 | 150 | 150 | 175 | 250 |

| Screw | M10 | M16 | M16 | M16 | M16 | M20 | M20 | M24 | M24 | M24 | M27 | M30 |

| Remark | N-plate quantity | |||||||||||

1. there are design drawings and equipment drawings, only need to send your drawings to our customer service or technical staff, we will be in accordance with your requirements for the program quotation!

2. Air volume, air inlet condition, shape size, chilled water inlet temperature, cooling supply (or air outlet condition requirements) and other parameters provided by the design drawings, or provide the corresponding parameters according to our measurement drawing.

3. as long as the process requirements of your process parameters to inform our customer service or technical personnel, our company can provide technical advice at any time!

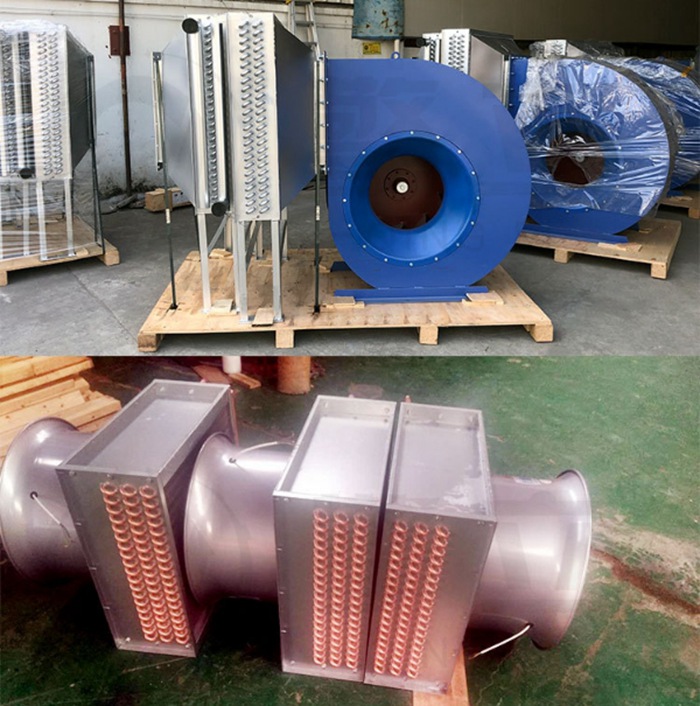

Our factory has over 20 years of experience as a manufacturer of ventilation and cooling equipment.

Professional Products:

1. We offer a range of professional products, including centrifugal fans, axial fans, duct fans, fan impellers, and mist fans.

2. We accommodate non-standard units and small orders.

3. Our accessories include forward impellers, backward impellers, axial impellers, and atomizers.

4. We specialize in ventilation and cooling solutions for industrial and commercial buildings.

Professional Manufacturing:

1. Our team of experienced engineers and R&D professionals supports product technology and development.

2. We have advanced manufacturing and inspection equipment, including laser cutting, CNC, dynamic balance, and product testing center.

3. Every product undergoes thorough inspection before delivery.

Professional Service:

1. Our products are exported to over 50 countries.

2. We prioritize on-time delivery.

3. All product have 3 years warranty.

4. Our experienced customer service team excels in communication, answering questions, and resolving issues.

Tags :

Hi! Click one of our members below to chat on