Buy Industrial Ventilation Fans Online

Buy Industrial Ventilation Fans Online

Liquid To Liquid Spiral Plate Heat Exchanger Stainless Steel Steam Water Heat Exchangers Non-standard Customized

Type :

Heat ExchangerPayment :

T/TOrder(MOQ) :

1 PCShipping Port :

GuangZhou, FoShanLead Time :

7-15 daysProduct Origin :

ChinaLiquid To Liquid Spiral Plate Heat Exchanger Stainless Steel Steam Water Heat Exchangers Non-standard Customized

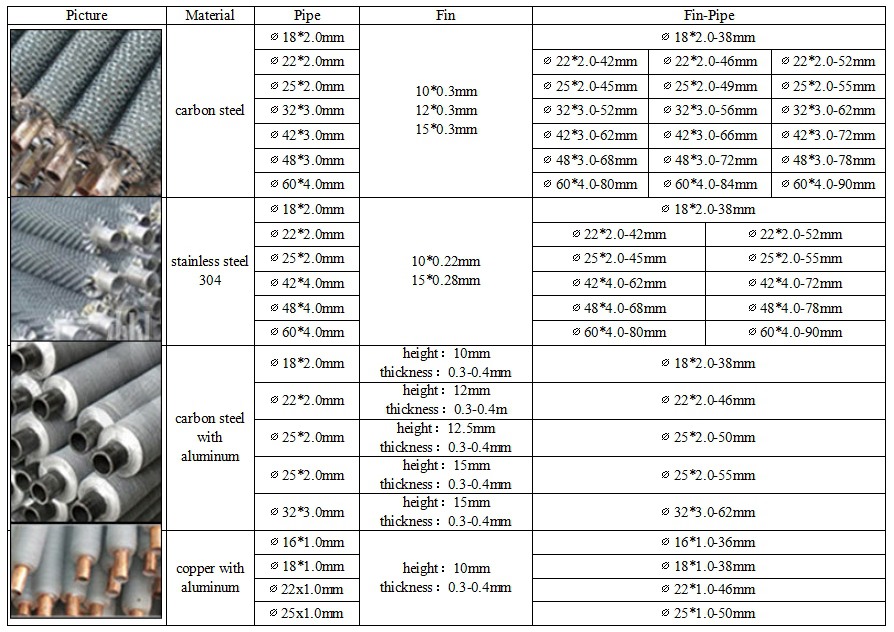

several material available:

carbon steel, stainless steel 304, copper, aluminum

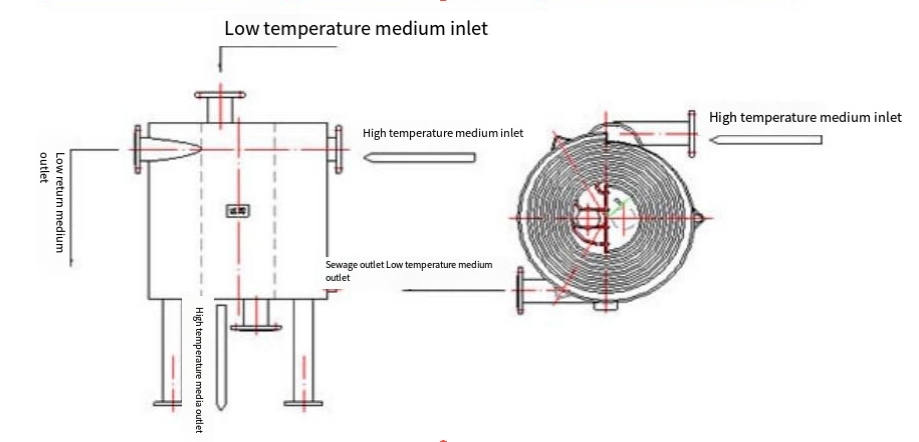

Spiral plate heat exchanger is a kind of high efficiency heat exchanger equipment, which is made of two spiral channels made of two parallel metal plates, and heat transfer between cold and hot fluids through the spiral plate wall. It is suitable for vapor-steam, vapor-liquid, liquid-liquid, and heat transfer to liquid. It is suitable for chemical, petroleum, solvent, medicine, food, light industry, textile, metallurgy, steel rolling, coking and other industries. According to the structure, it can be divided into non-detachable (type I) spiral plate and detachable (type II, type III) spiral plate heat exchangers.

How to choose spiral plate heat exchanger

1. The design pressure Pg is 0.6, 1.0, 1.6, 2.5MPa.

2. Allowable working temperature: carbon steel -20-200℃, stainless steel -20-250℃.

3. The equipment can be placed horizontally or vertically, but only vertically when used for steam condensation.

Main application fields: petroleum, electromechanical, chemical, light industry, food, sugar, medicine, textile printing and dyeing, steel rolling, coking plant.

Spiral plate heat exchanger features:

1. High heat transfer effect: the highest heat transfer coefficient of 3300W/ (m2.k), 1 to 3 times that of the column heat exchanger.

2. Strong self-cleaning ability: the medium takes a single channel, the spiral channel has no dead Angle, the flow rate is high, so the dirt is not easy to deposit, and the cleaning cycle is long.

3. Good energy saving effect: the heat transfer medium can carry out full countercurrent heat exchange, suitable for small temperature difference heat exchange, waste heat recovery, and make full use of low temperature heat energy.

4. Strong operation reliability: the non-detachable two channels are welded and sealed to ensure that the two working media are not mixed.

| Exchanger | Model | Plate Length (m) |

Area m² | Speed(m/h) Flow(m/h) |

Plate H(m) |

Diameter DN(mm) |

Diameter Dg(mm) |

Weight (kg) | ||

| PN0.6 | PN1.0 | PN1.6 | ||||||||

| 1 | IB 0.6(1.0,1.6)-1-0.2/300-6 | 6 | 1.07 | 3.97 | 0.2 | 300 | 40 | 40 | 48 | 50 |

| 2 | IB 0.6(1.0,1. 6)-2-0.6/400-6 | 6 | 2.08 | 3.97 | 0.2 | 400 | 40 | 70 | 80 | 85 |

| 4 | IB 0.6(1.0,1.6)-4-0.4/400-6 | 6 | 4.28 | 8.28 | 0.4 | 400 | 50 | 115 | 125 | 135 |

| IB 0.6(1.0,1.6)-4-0.4/500-10 | 10 | 4.95 | 13.42 | 0.4 | 500 | 65 | 145 | 185 | 205 | |

| 6 | IB 0.6(1.0, 1.6)-6-0.4/500-6 | 6 | 595 | 12. 62 | 0.6 | 400 | 65 | 160 | 190 | 215 |

| IB 0.6(1.0, 1.6)-6-0.5/500-10 | 10 | 6.28 | 17.00 | 0.5 | 500 | 80 | 170 | 220 | 240 | |

| 8 | IB 0.6(1.0,1.6)-8-0.4/500-6 | 6 | 7.19 | 8.28 | 0.4 | 500 | 50 | 180 | 210 | 215 |

| IB 0.6(1.0,1.6)-8-0.6/500-10 | 10 | 7.58 | 20.62 | 0.6 | 500 | 80 | 205 | 260 | 275 | |

| IB 0.6(1.0, 1.6)-8-0.5/600-10 | 10 | 8.69 | 17.01 | 0.5 | 600 | 80 | 235 | 285 | 315 | |

| 10 | IB 0.6(1.0, 1.6)-10-0.4/600-6 | 6 | 10.5 | 8.28 | 0.4 | 400 | 50 | 255 | 320 | 355 |

| IB 0.6(1.0,1.6)-10-0.6/600-10 | 10 | 8.67 | 20.62 | 0.6 | 600 | 80 | 265 | 360 | 395 | |

| IB 0.6(1.0,1.6)-10-0.6/700-14 | 14 | 9.33 | 28.28 | 0.6 | 700 | 100 | 320 | 415 | 470 | |

| IB 0.6(1.0,1.6)-10-0.5/700-14 | 14 | 7.70 | 23.24 | 0.5 | 700 | 100 | 385 | 360 | 390 | |

| 15 | IB 0.6(1.0,1.6)-15-0.5/700-6 | 6 | 18.07 | 10.44 | 0.5 | 700 | 65 | 450 | 695 | 720 |

| IB 0.6(1.0,1.6)-15-0.5/800-10 | 10 | 16.97 | 17.02 | 0.5 | 800 | 80 | 460 | 620 | 690 | |

| IB 0.6(1.0, 1.6)-15-0.8/700-14 | 14 | 14.27 | 38.31 | 0.8 | 700 | 100 | 445 | 615 | 680 | |

| 20 | IB 0.6(1.0,1.6)-20-0.6/700-6 | 6 | 21.78 | 12.62 | 0.6 | 700 | 65 | 460 | 605 | 715 |

| IB 0.6(1.0,1.6)-20-0.6/800-10 | 10 | 18.57 | 20.61 | 0.6 | 800 | 80 | 475 | 660 | 735 | |

| IB 0.6(1.0, 1.6)-20-0.8/800-14 | 14 | 19.7 | 38.33 | 0.8 | 800 | 100 | 580 | 775 | 830 | |

| 25 | IB 0.6(1.0,1.6)-25-0.5/800-6 | 6 | 24.83 | 10.45 | 0.5 | 800 | 65 | 560 | 710 | 795 |

| IB 0.6(1.0.1.6)-25-0.8/800-10 | 10 | 24.97 | 27.88 | 0.8 | 800 | 100 | 605 | 855 | 960 | |

| IB 0.6(1.0,1.6)-25-0.6/900-10 | 10 | 24.67 | 20.62 | 0.6 | 900 | 80 | 610 | 875 | 1010 | |

| IB 0.6(1.0,1.6)-25-0.8/900-14 | 14 | 25.86 | 38.33 | 0.8 | 900 | 100 | 620 | 890 | 1060 | |

| 30 | IB 0.6(1.0,1.6)-30-0.8/700-6 | 6 | 29.12 | 16.97 | 0.8 | 700 | 80 | 785 | 1120 | 1270 |

| IB 0.6(1.0,1.6)-30-1.0/800-10 | 10 | 31.37 | 35.02 | 1.0 | 800 | 100 | 825 | 1165 | 1310 | |

| IB 0.6(1.0,1.6)-30-0.8/1000-10 | 14 | 32.78 | 38.33 | 0.8 | 1000 | 100 | 860 | 1215 | 1370 | |

| 40 | IB 0.6(1.0,1.6)-40-0.8/1000-10 | 10 | 42.36 | 27.82 | 0.8 | 1000 | 100 | 1095 | 1445 | 1625 |

| IB 0.6(1.0,1.6)-40-1.0/1000-14 | 14 | 41.27 | 48.45 | 1.0 | 1000 | 125 | 1010 | 1400 | 1615 | |

| 50 | IB 0.6(1.0,1.6)-50-1.0/1000-10 | 10 | 53.26 | 35.05 | 1.0 | 1000 | 100 | 1160 | 1560 | 1755 |

| IB 0.6(1.0, 1. 6)-50-1.2/1000-14 | 14 | 49.77 | 58.50 | 1.2 | 1000 | 150 | 1090 | 1485 | 1680 | |

| 60 | IB 0.6(1.0,1.6)-60-0.8/1200-10 | 10 | 63.88 | 27.82 | 0.8 | 1200 | 100 | 1730 | 2065 | 2200 |

| IB 0.6(1.0,1.6)-60-1.0/1200-14 | 14 | 57.70 | 48.45 | 1.0 | 1200 | 125 | 1750 | 2147 | 2345 | |

| 80 | IB 0.6(1.0,1.6)-80-1.0/1200-10 | 10 | 80.28 | 35.05 | 1.0 | 1200 | 100 | 2240 | 2465 | 2570 |

| IB 0.6(1.0,1.6)-80-1.0/1400-14 | 14 | 81.01 | 48.45 | 1.0 | 1400 | 125 | 2347 | 2550 | 2685 | |

| 100 | IB 0.6(1.0,1.6)-1.0/1100-10 | 10 | 108.07 | 35.02 | 1.0 | 1400 | 100 | 3165 | 3385 | 3506 |

| IB 0.6(1.0, 1.6)-100-1.2/1400-14 | 14 | 97.72 | 58.53 | 1.2 | 1400 | 150 | 3105 | 3305 | 3443 | |

| IB 0.6(1.0,1.6)-100-1.0/1600-14 | 14 | 108.08 | 48.41 | 1.0 | 1600 | 125 | 3345 | 3585 | 3720 | |

1. there are design drawings and equipment drawings, only need to send your drawings to our customer service or technical staff, we will be in accordance with your requirements for the program quotation!

2. Air volume, air inlet condition, shape size, chilled water inlet temperature, cooling supply (or air outlet condition requirements) and other parameters provided by the design drawings, or provide the corresponding parameters according to our measurement drawing.

3. as long as the process requirements of your process parameters to inform our customer service or technical personnel, our company can provide technical advice at any time!

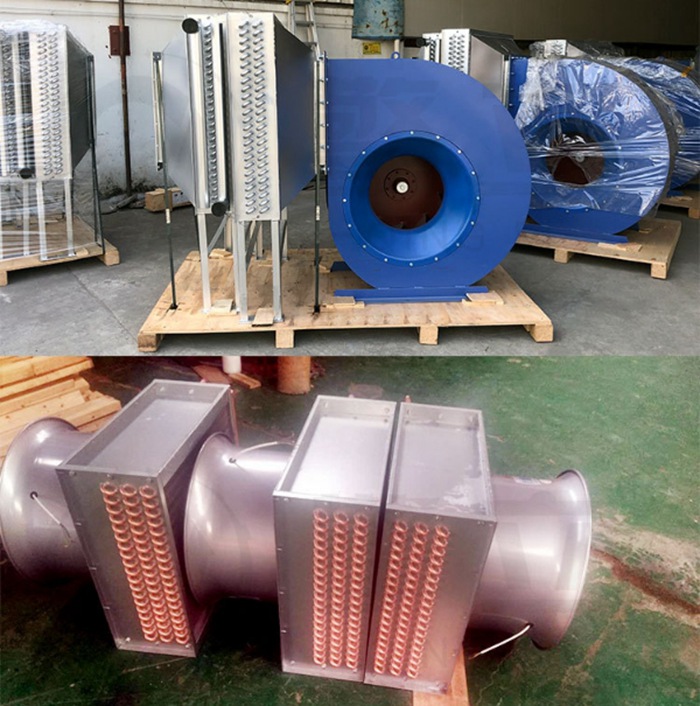

Our factory has over 20 years of experience as a manufacturer of ventilation and cooling equipment.

Professional Products:

1. We offer a range of professional products, including centrifugal fans, axial fans, duct fans, fan impellers, and mist fans.

2. We accommodate non-standard units and small orders.

3. Our accessories include forward impellers, backward impellers, axial impellers, and atomizers.

4. We specialize in ventilation and cooling solutions for industrial and commercial buildings.

Professional Manufacturing:

1. Our team of experienced engineers and R&D professionals supports product technology and development.

2. We have advanced manufacturing and inspection equipment, including laser cutting, CNC, dynamic balance, and product testing center.

3. Every product undergoes thorough inspection before delivery.

Professional Service:

1. Our products are exported to over 50 countries.

2. We prioritize on-time delivery.

3. All product have 3 years warranty.

4. Our experienced customer service team excels in communication, answering questions, and resolving issues.

Tags :

Hi! Click one of our members below to chat on