Buy Industrial Ventilation Fans Online

Buy Industrial Ventilation Fans Online

The Square Negative Pressure Exhaust Fan is a ventilation device that provides effective air circulation and pressure control in workshops, greenhouses, and poultry houses. It features low noise emissions, energy-efficient operation, substantial airflow capacity, and a straightforward installation process, making it suitable forindustrial and agricultural ventilation.

Type :

Exhaust FanPayment :

T/TOrder(MOQ) :

1 PCShipping Port :

GuangZhou, FoShanLead Time :

7-15 daysProduct Origin :

ChinaSquare Negative Pressure Exhaust Fan for Workshops, Greenhouses & Poultry Ventilation

The Square Negative Pressure Exhaust Fan is a ventilation device that provides effective air circulation and pressure control in workshops, greenhouses, and poultry houses. It features low noise emissions, energy-efficient operation, substantial airflow capacity, and a straightforward installation process, making it suitable forindustrial and agricultural ventilation.

This industrial exhaust fan supports ventilation in various settings such as warehouses, offices, flower greenhouses, and poultry facilities. It handles non-flammable, mildly corrosive gases at temperatures below 50℃, with relative humidity up to 80% and dust or solid impurity concentrations under 100mg/m³. Its robust design ensures consistent airflow, helping maintain a safe and comfortable environment for workers, plants, and livestock.

Applications & Benefits:

1.Workshop Ventilation: Improves air circulation in factories, storage areas, and industrial buildings.

2.Greenhouse Ventilation: Maintains optimal airflow for plant growth and temperature control.

3.Poultry Ventilation: Ensures fresh air for livestock, reducing heat stress and improving health.

4.Energy Efficiency & Low Noise: Reduces operational costs while providing quiet performance.

| Motor directly driven type | ||||||

| Model | Power(kW) | Voltage(V) | Rotation(r/min) | Volume(m³/h) | Noise dB(A) | Remarks |

| JS-II-4A | 0.37 | 220/380 | 1400 | 7200 | ≤73 | with louver\ with front-and-back protective net |

| JS-II-5A | 0.55 | 220/380 | 1400 | 8600 | ≤75 | |

| JS-11-6A | 0.25 | 220/380 | 720 | 17000 | ≤70 | |

| JS-11-8A | 0.4 | 220/380 | 520 | 23000 | ≤71 | |

| JS-1I-9A | 0.55 | 220/380 | 520 | 27500 | ≤73 | |

| JS-II-10A | 0.55 | 380 | 460 | 32000 | ≤74 | |

| JS-II-12A | 0.75 | 380 | 460 | 37000 | ≤75 | |

| JS-II-13A | 1.1 | 380 | 460 | 44500 | ≤78 | |

| JS-II-14A | 1.5 | 380 | 540 | 55000 | ≤82 | |

| Belt driven type | ||||||

| Model | Power(kW) | Voltage(V) | Rotation(r/min) | Volume(m³/h) | Noise dB(A) | Remarks |

| JS-II-7C | 0.55 | 220/380 | 520 | 18000 | ≤71 | with louver\ with front-and-back protective net |

| JS-1I-8C | 0.55 | 220/380 | 520 | 23000 | ≤71 | |

| JS-II-9C | 0.75 | 220/380 | 520 | 27500 | ≤73 | |

| JS-II-10C | 0.75 | 220/380 | 460 | 32000 | ≤74 | |

| JS-II-12C | 1.1 | 220/380 | 460 | 37000 | ≤75 | |

| JS-II-13C | 1.1 | 220/380 | 460 | 44500 | ≤78 | |

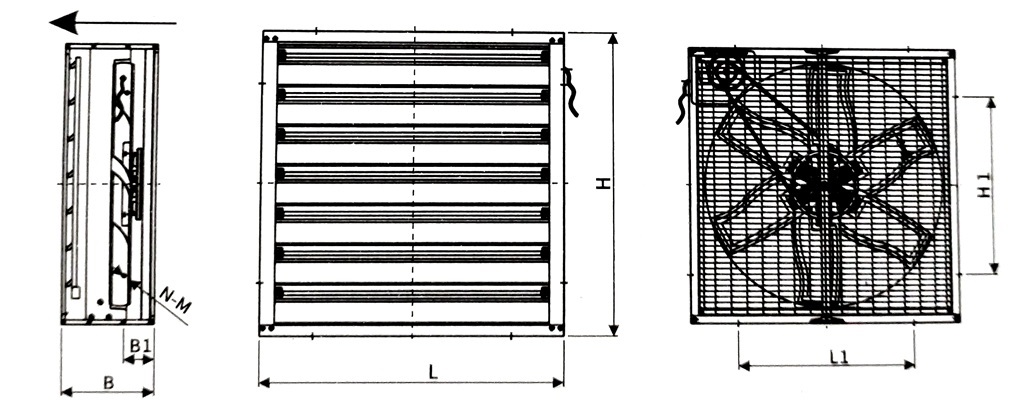

| C type with louver | Model | L | B | H | L1 | B1 | H1 | N-M | Blade Dia. | Weight(Kg) |

| 7C | 902 | 342 | 900 | 600 | 133 | 600 | 8-M8 | 680 | 39 | |

| 8C | 982 | 342 | 980 | 600 | 133 | 600 | 8-M8 | 780 | 41 | |

| 9C | 1052 | 342 | 1050 | 660 | 133 | 660 | 8-M8 | 880 | 44.5 | |

| 10C | 1112 | 342 | 1110 | 660 | 133 | 660 | 8-M8 | 965 | 46.5 | |

| 12C | 1222 | 342 | 1220 | 795 | 133 | 795 | 8-M8 | 1040 | 54 | |

| 13C | 1383 | 342 | 1381 | 795 | 133 | 795 | 8-M8 | 1220 | 60 | |

| 12C | 1222 | 402 | 1220 | 795 | 133 | 795 | 8-M8 | 1040 | 56 | |

| 13C | 1383 | 402 | 1381 | 795 | 133 | 795 | 8-M8 | 1220 | 62 | |

| A type with louver | Model | L | B | H | L1 | B1 | H1 | N-M | Blade Dia. | Weight(Kg) |

| 4A | 502 | 342 | 502 | - | - | - | - | 395 | 18 | |

| 5A | 602 | 342 | 602 | - | - | - | - | 495 | 22 | |

| 6A | 752 | 342 | 750 | - | - | - | 8-M8 | 580 | 82 | |

| 8A | 982 | 372 | 980 | 600 | 210 | 600 | 8-M8 | 780 | 45 | |

| 9A | 1052 | 372 | 1050 | 660 | 220 | 660 | 8-M8 | 880 | 50 | |

| 10A | 1112 | 372 | 1110 | 660 | 220 | 660 | 8-M8 | 965 | 55 | |

| 12A | 1222 | 402 | 1220 | 795 | 250 | 795 | 8-M8 | 1040 | 72 | |

| 13A | 1383 | 402 | 1381 | 600 | 250 | 795 | 8-M8 | 1220 | 86.5 | |

| 14A | 1480 | 390 | 1480 | 1060 | 150 | 1060 | 12-M8 | 1400 | 103 |

| A/C type with front-and-back protective net | Model | L | B | H | L1 | B1(A type) | B1(C type) | H1 | N-M | Blade Dia. | Weight(Kg) |

| 6A | 752 | 282 | 750 | 600 | 210 | - | 600 | 8-M8 | 580 | 28 | |

| 7C | 902 | 332 | 900 | 600 | 210 | 133 | 600 | 8-M8 | 680 | 34 | |

| 8A/8C | 982 | 332 | 980 | 600 | 210 | 133 | 600 | 8-M8 | 780 | 36.5/40 | |

| 9A/9C | 1052 | 332 | 1050 | 660 | 220 | 133 | 660 | 8-M8 | 880 | 39/43 | |

| 10A/10C | 1112 | 332 | 1110 | 660 | 220 | 133 | 660 | 8-M8 | 965 | 41/48 | |

| 12A | 1222 | 362 | 1220 | 795 | -- | 133 | 795 | 8-M8 | 1040 | 46 | |

| 12C | 1222 | 332 | 1220 | 795 | - | 133 | 795 | 8-M8 | 1040 | 51.5 | |

| 13A | 1383 | 362 | 1381 | 795 | 250 | - | 795 | 8-M8 | 1220 | 62.5 | |

| 13C | 1383 | 332 | 1381 | 795 | 250 | - | 795 | 8-M8 | 1220 | 76 |

Customization Capabilities

1. Drawing-Based Customization

Provide system or equipment drawings for accurate design alignment and quotation.

2. Parameter-Based Customization

Tailored by air volume, inlet/outlet temperature, structural dimensions, etc. On-site measurement is supported.

3. Technical Support

24/7 consultation on heat-exchange solutions and process parameter guidance.

Tags :

Hi! Click one of our members below to chat on