Buy Industrial Ventilation Fans Online

Buy Industrial Ventilation Fans Online

High-Pressure Axial Flow Fan for Industrial Ventilation and Exhaust is a ventilation device used for moving large volumes of air through industrial spaces such as factories, workshops, and warehouses. This type of industrial axial flow blower delivers strong airflow, steady pressure, and efficient power use, making it suitable for daily ventilation, exhaust, cooling, and smoke extraction in a wide range of working conditions.

Type :

Axial Flow FanPayment :

T/TOrder(MOQ) :

1 PCShipping Port :

GuangZhou, FoShanLead Time :

7-15 daysProduct Origin :

ChinaHigh-Pressure Axial Flow Fan for Industrial Ventilation and Exhaust

High-Pressure Axial Flow Fan for Industrial Ventilation and Exhaust is a ventilation device used for moving large volumes of air through industrial spaces such as factories, workshops, and warehouses. This type of industrial axial flow blower delivers strong airflow, steady pressure, and efficient power use, making it suitable for daily ventilation, exhaust, cooling, and smoke extraction in a wide range of working conditions.

Product Details

This industrial axial flow blower supports both ventilation and exhaust, and can be built with reversible airflow when needed. It maintains a compact structure, stable output, and low noise during long-term operation. The blower is commonly used in industrial ventilation systems across petroleum processing, alcohol production, painting lines, spray-drying equipment, rubber plants, food processing areas, and pharmaceutical workshops.

The high-pressure axial flow fan handles non-corrosive gases with dust or solid content up to 150mg/m³ and operates safely under temperatures below 50°C.

Multiple material options—mild steel, stainless steel (304/316/316L), and aluminum alloy—allow the blower to adapt to different environments and process requirements.

The impeller is produced with a 400-ton die-casting method, ensuring high strength and stable air performance. All key parameters, including pressure and airflow, are tested to provide reliable data for engineering use.

| Model | Power(kW) | Rotation(r/min) | Adjustable blade angle | Volume(m³/h) | Pressure(Pa) |

| 3A | 0.12 | 2800 | 20 | 2184~1811 | 114~157 |

| 0.37 | 2800 | 35 | 3866~3261 | 179~211 | |

| 3.5A | 0.55 | 2800 | 27 | 4204~3392 | 224~285 |

| 0.75 | 2800 | 30 | 4998~4094 | 321~356 | |

| 0.09 | 1400 | 30 | 2307~1818 | 77~107 | |

| 0.12 | 1400 | 35 | 2499~2047 | 80~112 | |

| 4A | 1.1 | 2800 | 25 | 6080~4960 | 285~398 |

| 1.5 | 2800 | 35 | 7600~6150 | 305~428 | |

| 0.18 | 1400 | 32 | 3800~3075 | 77~107 | |

| 0.25 | 1400 | 35 | 4675~3900 | 80~112 | |

| 5A | 1.5 | 2800 | 18 | 9354~8023 | 242~321 |

| 2.2 | 2800 | 25 | 11032~9400 | 337~410 | |

| 0.37 | 1400 | 28 | 6809~5495 | 103~129 | |

| 0.55 | 1400 | 30 | 8096~6631 | 147~163 | |

| 6A | 3 | 2900 | 17 | 15217~12125 | 283~537 |

| 5.5 | 2900 | 21 | 18888~15673 | 432~729 | |

| 0.75 | 1450 | 27 | 10611~8338 | 140~193 | |

| 1.1 | 1450 | 32 | 12294~9455 | 187~222 | |

| 7A | 2.2 | 1450 | 33 | 22170~16939 | 239~295 |

| 3 | 1450 | 38 | 23973~18777 | 294~322 | |

| 0.55 | 960 | 29 | 11821~8705 | 90~117 | |

| 0.75 | 960 | 33 | 13477~11345 | 118~131 | |

| 8A | 4 | 1450 | 24 | 24327~18162 | 295~404 |

| 7.5 | 1450 | 37 | 36427~29916 | 503~532 | |

| 1.1 | 960 | 24 | 16409~13560 | 140~173 | |

| 1.5 | 960 | 29 | 18535~15244 | 169~197 | |

| 9A | 5.5 | 1450 | 24 | 39902~33582 | 296~422 |

| 11 | 1450 | 33 | 48488~38655 | 543~620 | |

| 2.2 | 960 | 27 | 26795~18695 | 178~232 | |

| 3 | 960 | 33 | 31170~24568 | 232~265 | |

| 10A | 7.5 | 1450 | 23 | 40805~29579 | 312~528 |

| 18.5 | 1450 | 35 | 61360-47436 | 638~712 | |

| 4 | 960 | 32 | 37375~30479 | 263~300 | |

| 5.5 | 960 | 35 | 40540~33861 | 297~323 | |

| 11.2A | 7.5 | 960 | 33 | 54117~45622 | 340~356 |

| 11 | 960 | 38 | 57421-50499 | 364~384 | |

| 12A | 15 | 960 | 35 | 78463-63230 | 394-461 |

| 18.5 | 960 | 40 | 86505-75764 | 451~488 |

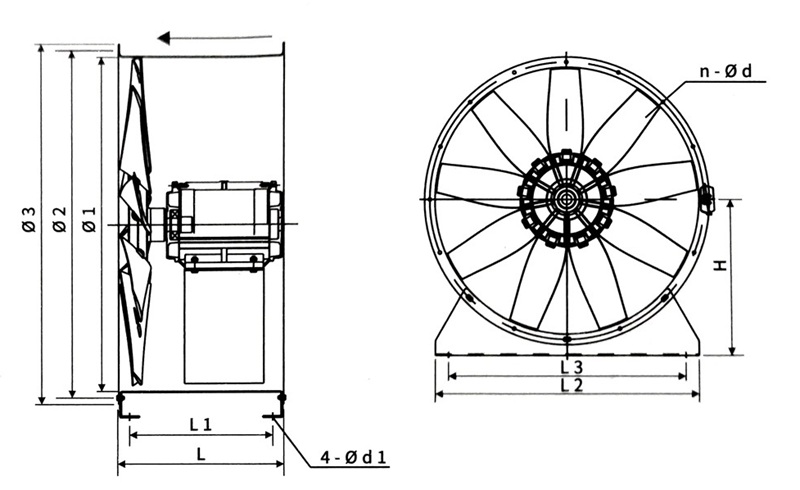

| Model | Motor Power(kW) | Flange | Dimension | Weight(Kg) | ||||||||

| ∅1 | ∅2 | ∅3 | n-∅d | L | L1 | L2 | L3 | H | 4-∅d1 | |||

| 3A | 63-2 0.12kW | 310 | 330 | 360 | 3-08 | 280 | 224 | 260 | 197 | 195 | 4-10x18 | 12 |

| 71-2 0.37kW | 16 | |||||||||||

| 3.5A | 63-4 0.09kW 63-4 0.12kW |

360 | 380 | 410 | 4-08 | 280 | 230 | 300 | 240 | 225 | 4-10x18 | 13 |

| 71-2 0.55kW 71-2 0.75kW |

18 | |||||||||||

| 4A | 90S-2 1.5kW 71-2 1.1kW |

410 | 430 | 460 | 4-08 | 350 | 289 | 350 | 286 | 250 | 4-10x18 | 29.5 19 |

| 300 | 239 | |||||||||||

| 63-4 0.18kW 63-4 0.25kW |

13.5 | |||||||||||

| 5A | 90S-2 1.55W 90L-2 2.2kW 71-4 0.37kW 71-4 0.55kW |

510 | 530 | 565 | 4-08 | 350 | 290 | 450 | 386 | 310 | 4-10x18 | 33.5 38 |

| 300 | 240 | 22 | ||||||||||

| 6A | 132S-2 5.5kW | 610 | 650 | 680 | 6-011 | 450 | 395 | 550 | 472 | 373 | 4-10x18 | 89 |

| 100L-2 3kW | 630 | 665 | 6-08 | 370 | 303 | 52 | ||||||

| 71-4 0.75kW 90S-4 1.1kW |

36 | |||||||||||

| 41.5 | ||||||||||||

| 7A | 100L-4 2.2kW | 710 | 735 | 770 | 8-08 | 425 | 358 | 650 | 570 | 420 | 4-10x18 | 59 |

| 100L-4 3kW | 63 | |||||||||||

| 71-6 0.55kW 90S-6 0.75kW |

370 | 303 | 42 | |||||||||

| 45 | ||||||||||||

| 8A | 132M-4 7.5kW | 810 | 835 | 870 | 8-08 | 500 | 424 | 750 | 650 | 462 | 4-14x28 | 121 |

| 112M-4 4kW | 425 | 349 | 87 | |||||||||

| 90L-6 1.1kW 100L-6 1.5kW |

67 | |||||||||||

| 68.5 | ||||||||||||

| 9A | 160M-4 11kW 132S-4 5.5kW 112M-6 2.2kW 132S-6 3kW |

910 | 950 | 990 | 8-011 | 620 | 555 | 850 | 750 | 525 | 4-14x28 | 187 |

| 500 | 435 | 125 | ||||||||||

| 103 | ||||||||||||

| 119 | ||||||||||||

| 10A | 180M-4-18.5kW 132M-4-7.5kW 132M-6-4kW 132M-6-5.5kW |

1010 | 1050 | 1090 | 8-011 | 680 | 615 | 1000 | 900 | 575 | 4-14x28 | 286 |

| 500 | 435 | 158 | ||||||||||

| 151 | ||||||||||||

| 161 | ||||||||||||

| 11.2A | 160M-6-7 5kW 160L-6-11kW |

1130 | 1180 | 1230 | 8-011 | 680 | 610 | 1100 | 1000 | 645 | 4-14x28 | 220 |

| 239 | ||||||||||||

| 12A | 180L-6-15kW 200L-6-18.5kW |

1210 | 1260 | 1310 | 8-011 | 750 | 673 | 1200 | 1100 | 680 | 4-16x28 | 305 |

| 355 | ||||||||||||

Advantages

Compact structure for the industrial axial flow blower

Material options for different working conditions (Steel / Stainless Steel / Aluminum Alloy)

Air performance tested for accurate and dependable results

Heavy-duty die-cast aluminum alloy impeller

Strong airflow and stable high-pressure performance

Applications

Building ventilation, exhaust, and air circulation

Firefighting and emergency smoke extraction

Filtration systems, drying equipment, food processing lines

Painting rooms, spray booths, and pharmaceutical production

Tags :

Hi! Click one of our members below to chat on